The Beauty and Genius of the Fairmount Water Works

The Beauty and Genius of the Fairmount Water Works

Philadelphia had a problem with filth. In an era when civic virtue was at its zenith, the city found a mechanically ingenious solution to bringing clean water to its citizens.

Philadelphia, in the late 18th century—still the capital of the country—was the second largest city, albeit roughly the size of one of today’s college towns. And it was, like most cities of the time, filthy. The primary mode of transportation—the horse—left its waste in the streets, as did the households that lined them. There was no running water to wash any of it away, or to put out any fire that might occur, or to drink.

The row house lots that were common at the time were a mere 20 feet long. In addition to the house, there was a backyard, with a well in one corner and the outhouse in the other. “So you’re basically drawing your water out of the same ground that all your waste is going into,” said Adam Levine, a historical consultant for the Philadelphia water department. “They didn’t know about microbes, but they knew that you don’t want to drink your own piss and eat your own . . . you know.”

The city had had a few yellow fever outbreaks, caused by mosquitos arriving on ships from the Caribbean, but they didn’t understand that at the time. Instead, they blamed rotting vegetables, bad air, and poor sanitation. So, when the disease killed 10 percent of the population in 1793, the city decided to act.

“People demanded that the city government do something,” said A. Leonard Pundt, a Fairmount Water Works historian and author of Fairmount Water Works: The surprising history of an American landmark. “And, so, what do city governments do? They create a committee. In this case, it was very effective.”

The Joint Committee of the Select and Common Councils, as the committee was called, decided that if they could distribute water throughout the city, the people would have something cleaner to drink, something with which to clean the streets, and maybe they could control the yellow fever situation.

Exactly how they would get water flowing through the city was debated by the committee, argued about among legislators, and discussed among mechanics. And these deliberations touched off a series of events and innovations that led to a masterpiece of civic infrastructure, so prized for its ingenuity and beauty that it became an international tourist attraction and an mechanical engineering landmark.

What was on the cutting edge of Latrobe’s plans was the use of steam engines. At that time there were only three in the country—this was before the birth of the railroad. “It was a new technology,” Levine said, “and he wanted to do the do it in a modern way.”

Latrobe’s vision became reality in January of 1801. The first of a pair of steam engines built by his partner, Nicholas Roosevelt, raised water to a pipe under Chestnut Street. Gravity would take it Center Square where the second steam engine would lift the water to reservoir tanks at the top of the pump house. From there it would run through the bored-out logs to hydrants throughout the city and to the homes of paying customers.

This was a glorious thing, no doubt. But there were some problems.

For one thing, the pipes were leaky. The reservoir tanks were so small that, without water coming in, they would empty in half an hour. The water distribution did nothing to end yellow fever, of course, and there were repeated outbreaks over the years. The steam engine housing was so tight that Frederic Graff, Latrobe’s assistant (who would go on to be the superintendent of the waterworks until his death in 1847), didn’t have enough room to make repairs. Two men died in 1801 when a fire broke out in one of the boilers (one man died trying to rescue the other). And, on top of it all, the waterworks cost a lot more to operate than it was bringing in.

So, in 1811, the Watering Committee turned to Graff and another previous Latrobe assistant, John Davis, to improve upon what Latrobe had started. They found a spot on the Schuylkill next to Fairmount Hill, the peak of which was 102 feet above the river and, just as important, fifty-six feet above the city’s highest point at that time. Their plan was to pump water from the river with new steam engines to a reservoir they would build at the top the hill, which would hold three million gallons. Water could then flow downhill to wherever it was needed.

In August of 1812, construction of the reservoir began. In 1815 a new steam engine was built to pump water up the hill. It was a low-pressure condensing Boulton and Watt design with a 44-inch cylinder and a 72-inch stroke—not unlike the waterworks’ previous engines—and it was built by Eagle Works owner Samuel Richards. A second, more powerful engine, a high-pressure non-condensing engine that operated at 100 horsepower, invented (essentially simultaneously with Britain’s Richard Trevithick) by Mars Works owner Owen Evans, took over in 1817. Evans promised that the new engine could pump three and half million gallons a day.

And Graff, remaining true to Latrobe’s architectural vision, built handsome neoclassical buildings to house the engines.

The water went up through a cast iron main, but it went down through five wooden mains before it reached the still wooden plumbing. That network had grown to 32 miles, and 3,500 households, by 1817.

And the engines were dangerous.

“The problem was that boiler technology had not advanced along with engine technology, so you still had wooden boilers, and then metal boilers,” Pundt said. “Because of the higher pressures needed and the higher temperatures, the metal would soften, and it would sag, and it would cause literal explosions of the boiler.” Two such explosions killed a worker in June of 1818 and two in October of 1821.

So the city shut down the engines a year later and they lay idle until 1832, when they were sold for their parts. The building that housed the engines became a saloon.

This, however, was not the sad ending of the Fairmount Water Works, but the beginning of its era of resplendence.

The Watering Committee, sick of the failures brought about by use of high-tech steam engines, decided to take a step back to make a leap forward. A new waterworks would use the well-worn concept of the waterwheel. Three, actually, to start with, and eventually eight.

And they would require a dam.

The first stone-filled cribs of hickory that would dam the Schuylkill were lowered into the river in the spring of 1819. The last were lowered a year and three months later. At 2,008 feet, it was the longest dam in the country. And on July 1, 1822, the first wheel began to turn.

They were breast wheels—a tight stone channel surrounded the lower half of each wheel—so they took advantage of the full weight of water passing over it. Compared to the lethal steam engines, the new system was safe and wildly efficient. Raising a little more than three million gallons a day had cost $206 with the engines. Now it cost $4.

And the wheels were something to look at. At 15 feet wide with a diameter of 15 to 18 feet, they were more like massive spindles than the waterwheels you might see at a typical mill. Graff designed the handsome buildings that housed them so that sightseers could come in and view the wheels in action. “When the waterwheels were put in operation, people couldn’t believe that something could be so quiet and be doing so much work and so much pumping,” Levine said. “There’s no combustion, no noise, just the water wheels turning, the water splashing.”

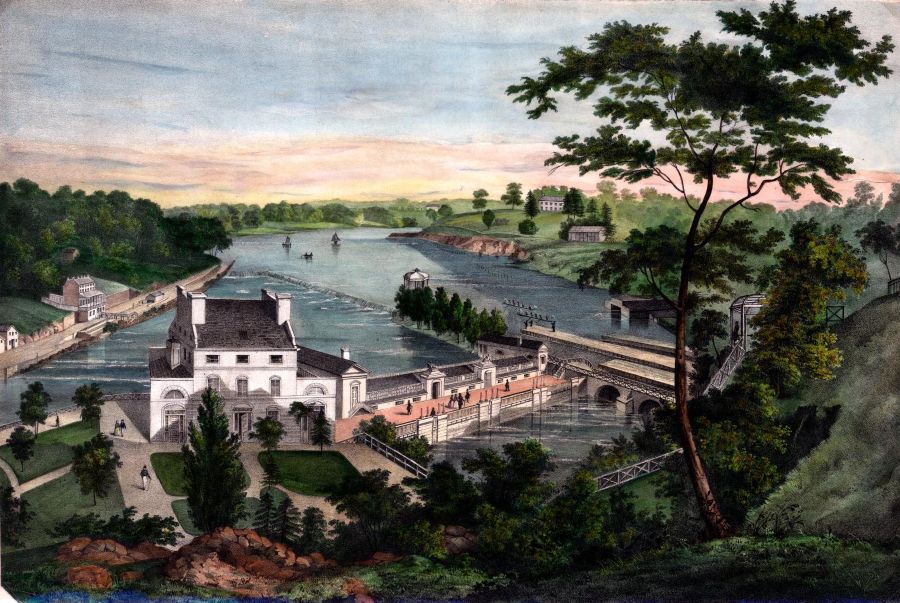

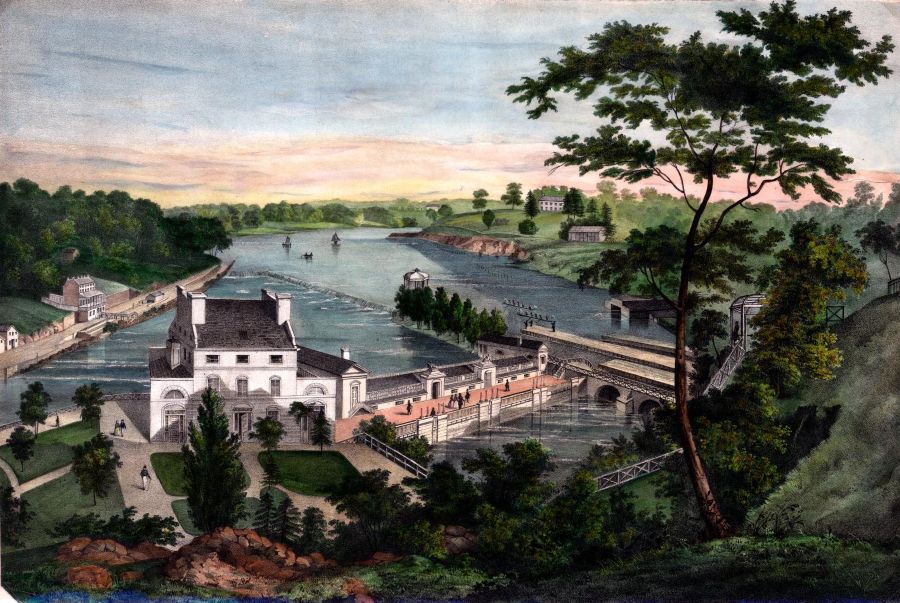

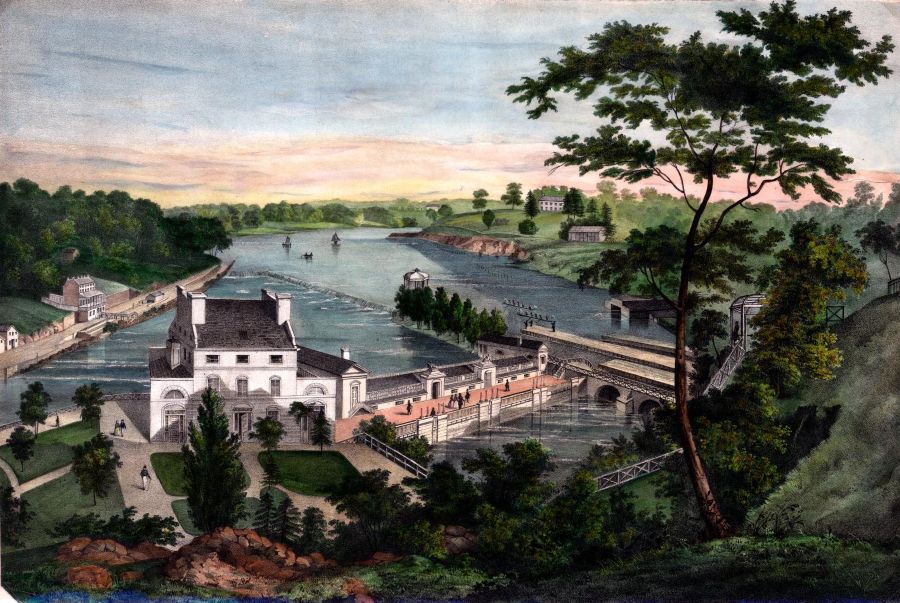

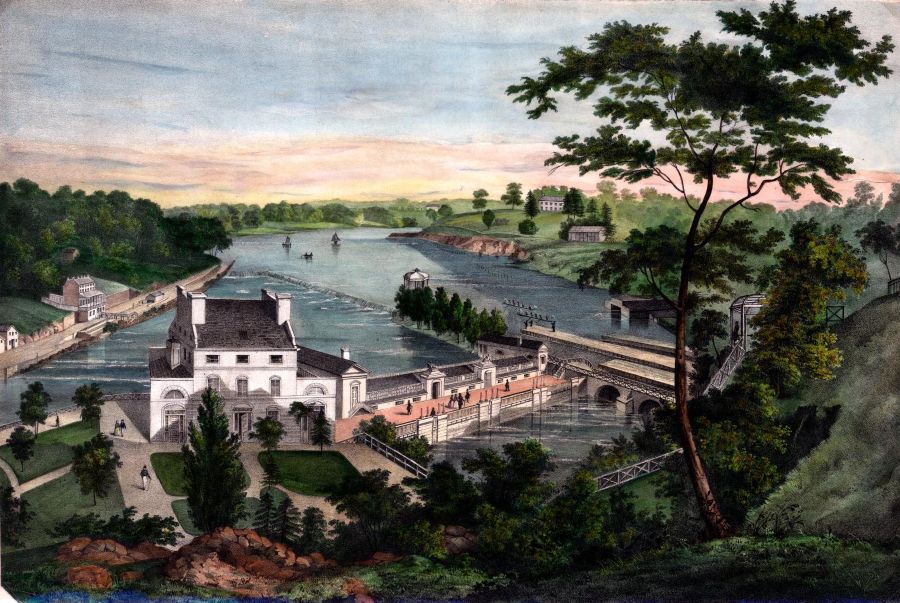

In fact, the dam-made pond, the park around the wheels and pumps, and the reservoir at the top of the hill all became a triumph of public space. Don’t take our word for it. Here’s Charles Dickens, reporting on his visit: “The Water Works, which are on a height near the city, are no less ornamental than useful, being tastefully laid out as a public garden, and kept in the best and neatest order.”

Anthony Trollope, too, visited, and said that “interesting and curious as this machinery is, Fair Mount would not be so attractive had it not something else to offer. It is, in truth, one of the very prettiest spots the eye can look upon.” And Mark Twain, living in Philadelphia at the time, wrote to his brother about it: “Seeing a park at the foot of the hill, I entered—and found it one of the nicest little places about. Fat marble Cupids, in big marble vases, squirted water upward incessantly.”

With eight wheels turning, the waterworks distributed more than five million gallons of water throughout the city each day. Thirst was quenched, fires doused, and, perhaps most impressively, the streets were cleaned. “Visitors wrote that they had to wear rubber boots to walk down the sidewalk in the morning because water was being sprayed here, there and everywhere,” Levine said. Delivering all that water cost $29,713 a year, but earned $151,501. Some of those profits came from areas just outside of Philadelphia who wanted in on the water action—but they had to pay an addition 50 percent.

The waterworks were such a success that Graff went on to consult for dozens of new waterworks across the country and the globe. Graff’s son eventually took over where his father left off and he fought to keep the Fairmount Water Works safe from industry.

Pollution increased over the next 40 years, as industry continued to dump waste in the river—despite the laws attempting to prevent such behavior—and filtration plants began to appear throughout the city. The Fairmount Water Works was decommissioned in 1909. And though its days of distributing water were over it would still display water for the next 50 years: it became an aquarium till that closed, too, in 1962. But in 1975 the American Society of Civil Engineers made it a civil engineering landmark, and in 1977 ASME followed suit, making it a mechanical engineering landmark as well.

The Fairmount Water Works was an exemplar of beauty and technological advancements in its century-long life, to be sure. But it was also an example of governance at its best.

“It was the municipality providing water to its citizens, and if you didn’t want to have a pipe put into your house, you could get it free of charge at the hydrant,” Levine said. “We were the first city in this country to provide it as a municipal service. It wasn’t a private company trying to make money. It was the city doing a sort of Quaker thing, trying to serve its citizens.”

Michael Abrams is a technology writer in Westfield, N.J.

The row house lots that were common at the time were a mere 20 feet long. In addition to the house, there was a backyard, with a well in one corner and the outhouse in the other. “So you’re basically drawing your water out of the same ground that all your waste is going into,” said Adam Levine, a historical consultant for the Philadelphia water department. “They didn’t know about microbes, but they knew that you don’t want to drink your own piss and eat your own . . . you know.”

The city had had a few yellow fever outbreaks, caused by mosquitos arriving on ships from the Caribbean, but they didn’t understand that at the time. Instead, they blamed rotting vegetables, bad air, and poor sanitation. So, when the disease killed 10 percent of the population in 1793, the city decided to act.

“People demanded that the city government do something,” said A. Leonard Pundt, a Fairmount Water Works historian and author of Fairmount Water Works: The surprising history of an American landmark. “And, so, what do city governments do? They create a committee. In this case, it was very effective.”

The Joint Committee of the Select and Common Councils, as the committee was called, decided that if they could distribute water throughout the city, the people would have something cleaner to drink, something with which to clean the streets, and maybe they could control the yellow fever situation.

Exactly how they would get water flowing through the city was debated by the committee, argued about among legislators, and discussed among mechanics. And these deliberations touched off a series of events and innovations that led to a masterpiece of civic infrastructure, so prized for its ingenuity and beauty that it became an international tourist attraction and an mechanical engineering landmark.

Power pumps

The Joint Committee eventually enlisted Benjamin Henry Latrobe, the architect who would go on to design much of the country’s capital, and who was in town to work on the Bank of Pennsylvania. Latrobe wanted to pump water from the Schuylkill River, essentially the western border of the settled parts of the city, and send it around to the citizens in hollowed-out logs. This was not exactly novel. Waterwheels and water distribution systems had been bringing the potable to populations for thousands of years. The town of Bethlehem, Pennsylvania had been using a waterwheel to send water to its denizens through pipes of hemlock (and later pipes of lead—pick your poison) since 1762.What was on the cutting edge of Latrobe’s plans was the use of steam engines. At that time there were only three in the country—this was before the birth of the railroad. “It was a new technology,” Levine said, “and he wanted to do the do it in a modern way.”

Latrobe’s vision became reality in January of 1801. The first of a pair of steam engines built by his partner, Nicholas Roosevelt, raised water to a pipe under Chestnut Street. Gravity would take it Center Square where the second steam engine would lift the water to reservoir tanks at the top of the pump house. From there it would run through the bored-out logs to hydrants throughout the city and to the homes of paying customers.

This was a glorious thing, no doubt. But there were some problems.

For one thing, the pipes were leaky. The reservoir tanks were so small that, without water coming in, they would empty in half an hour. The water distribution did nothing to end yellow fever, of course, and there were repeated outbreaks over the years. The steam engine housing was so tight that Frederic Graff, Latrobe’s assistant (who would go on to be the superintendent of the waterworks until his death in 1847), didn’t have enough room to make repairs. Two men died in 1801 when a fire broke out in one of the boilers (one man died trying to rescue the other). And, on top of it all, the waterworks cost a lot more to operate than it was bringing in.

So, in 1811, the Watering Committee turned to Graff and another previous Latrobe assistant, John Davis, to improve upon what Latrobe had started. They found a spot on the Schuylkill next to Fairmount Hill, the peak of which was 102 feet above the river and, just as important, fifty-six feet above the city’s highest point at that time. Their plan was to pump water from the river with new steam engines to a reservoir they would build at the top the hill, which would hold three million gallons. Water could then flow downhill to wherever it was needed.

In August of 1812, construction of the reservoir began. In 1815 a new steam engine was built to pump water up the hill. It was a low-pressure condensing Boulton and Watt design with a 44-inch cylinder and a 72-inch stroke—not unlike the waterworks’ previous engines—and it was built by Eagle Works owner Samuel Richards. A second, more powerful engine, a high-pressure non-condensing engine that operated at 100 horsepower, invented (essentially simultaneously with Britain’s Richard Trevithick) by Mars Works owner Owen Evans, took over in 1817. Evans promised that the new engine could pump three and half million gallons a day.

And Graff, remaining true to Latrobe’s architectural vision, built handsome neoclassical buildings to house the engines.

The water went up through a cast iron main, but it went down through five wooden mains before it reached the still wooden plumbing. That network had grown to 32 miles, and 3,500 households, by 1817.

Raising grace

Despite the improvements and the greater water flow, all was not well. For one thing, a dry spell proved that, however huge the reservoir and powerful the engines, only a million gallons could work its way through the system thanks to the small bore of the logs and continued leaking. The addition of spigot joints (essentially a narrow nose on one end of a log that fit into the a wider funnel shape on the end of another log) and curved cast iron for wherever there were bends, improved flow somewhat. But costs were still high—more than $30,000 a year per engine.And the engines were dangerous.

“The problem was that boiler technology had not advanced along with engine technology, so you still had wooden boilers, and then metal boilers,” Pundt said. “Because of the higher pressures needed and the higher temperatures, the metal would soften, and it would sag, and it would cause literal explosions of the boiler.” Two such explosions killed a worker in June of 1818 and two in October of 1821.

So the city shut down the engines a year later and they lay idle until 1832, when they were sold for their parts. The building that housed the engines became a saloon.

This, however, was not the sad ending of the Fairmount Water Works, but the beginning of its era of resplendence.

The Watering Committee, sick of the failures brought about by use of high-tech steam engines, decided to take a step back to make a leap forward. A new waterworks would use the well-worn concept of the waterwheel. Three, actually, to start with, and eventually eight.

And they would require a dam.

The first stone-filled cribs of hickory that would dam the Schuylkill were lowered into the river in the spring of 1819. The last were lowered a year and three months later. At 2,008 feet, it was the longest dam in the country. And on July 1, 1822, the first wheel began to turn.

They were breast wheels—a tight stone channel surrounded the lower half of each wheel—so they took advantage of the full weight of water passing over it. Compared to the lethal steam engines, the new system was safe and wildly efficient. Raising a little more than three million gallons a day had cost $206 with the engines. Now it cost $4.

And the wheels were something to look at. At 15 feet wide with a diameter of 15 to 18 feet, they were more like massive spindles than the waterwheels you might see at a typical mill. Graff designed the handsome buildings that housed them so that sightseers could come in and view the wheels in action. “When the waterwheels were put in operation, people couldn’t believe that something could be so quiet and be doing so much work and so much pumping,” Levine said. “There’s no combustion, no noise, just the water wheels turning, the water splashing.”

In fact, the dam-made pond, the park around the wheels and pumps, and the reservoir at the top of the hill all became a triumph of public space. Don’t take our word for it. Here’s Charles Dickens, reporting on his visit: “The Water Works, which are on a height near the city, are no less ornamental than useful, being tastefully laid out as a public garden, and kept in the best and neatest order.”

Anthony Trollope, too, visited, and said that “interesting and curious as this machinery is, Fair Mount would not be so attractive had it not something else to offer. It is, in truth, one of the very prettiest spots the eye can look upon.” And Mark Twain, living in Philadelphia at the time, wrote to his brother about it: “Seeing a park at the foot of the hill, I entered—and found it one of the nicest little places about. Fat marble Cupids, in big marble vases, squirted water upward incessantly.”

With eight wheels turning, the waterworks distributed more than five million gallons of water throughout the city each day. Thirst was quenched, fires doused, and, perhaps most impressively, the streets were cleaned. “Visitors wrote that they had to wear rubber boots to walk down the sidewalk in the morning because water was being sprayed here, there and everywhere,” Levine said. Delivering all that water cost $29,713 a year, but earned $151,501. Some of those profits came from areas just outside of Philadelphia who wanted in on the water action—but they had to pay an addition 50 percent.

The waterworks were such a success that Graff went on to consult for dozens of new waterworks across the country and the globe. Graff’s son eventually took over where his father left off and he fought to keep the Fairmount Water Works safe from industry.

In decline

The era of the Fairmount Water Works’ wondrous waterwheels began to come to end in the middle of the century when the first turbine was installed. By 1872 three efficient turbines had replaced all the water wheels. The turbines did their thing underwater, so only the gears they turned were visible to visitors to the waterworks.Pollution increased over the next 40 years, as industry continued to dump waste in the river—despite the laws attempting to prevent such behavior—and filtration plants began to appear throughout the city. The Fairmount Water Works was decommissioned in 1909. And though its days of distributing water were over it would still display water for the next 50 years: it became an aquarium till that closed, too, in 1962. But in 1975 the American Society of Civil Engineers made it a civil engineering landmark, and in 1977 ASME followed suit, making it a mechanical engineering landmark as well.

The Fairmount Water Works was an exemplar of beauty and technological advancements in its century-long life, to be sure. But it was also an example of governance at its best.

“It was the municipality providing water to its citizens, and if you didn’t want to have a pipe put into your house, you could get it free of charge at the hydrant,” Levine said. “We were the first city in this country to provide it as a municipal service. It wasn’t a private company trying to make money. It was the city doing a sort of Quaker thing, trying to serve its citizens.”

Michael Abrams is a technology writer in Westfield, N.J.