Device Extracts Hydrogen from Seawater

Device Extracts Hydrogen from Seawater

A new low-cost technology produces carbon-free hydrogen via solar-powered electrolysis of seawater—and generates potable water as a byproduct.

Rising global demand for hydrogen is pushing researchers to reinvent sustainable production methods. A team of researchers at Cornell University, in partnership with Lehigh University, Johns Hopkins University, and Michigan State University, has done just that with a new breakthrough: A compact, solar-powered device that turned seawater into hydrogen fuel and clean drinking water without relying on electricity or freshwater.

To develop the apparatus, the team tackled two major obstacles: seawater corrosion and waste heat loss. They designed the system to harness the full solar spectrum. High-energy light powers a photovoltaic panel to generate electricity. Meanwhile, waste heat and low-energy light powers a photothermal process. On the panel’s backside, a wicking evaporator passively pulls in seawater. The panel’s heat vaporizes water, leaving the concentrated brine behind.

“A siphon effect drove a gentle, continuous fluid flow through the evaporator, from inlet to outlet. This steady movement was strong enough to create a flushing action, effectively sweeping out the brine and carrying seawater through the system,” explained Lenan Zhang, assistant professor at Cornell’s Sibley School of Mechanical and Aerospace Engineering.

Water vapor condenses across a narrow gap directly onto the electrolyzer, which then uses electricity from the solar panel to split water into hydrogen and oxygen, collecting hydrogen for energy storage or use.

More for You: Microwaves Could Make for Greener Hydrogen

Evaporation cools the solar panel, enhancing electricity production, while the condensation process warms the electrolyzer, boosting hydrogen output. By combining solar energy, seawater evaporation, and electrolysis in one streamlined system, the device offers a scalable, sustainable way to produce green hydrogen and clean water, especially in off-grid or water-scarce regions.

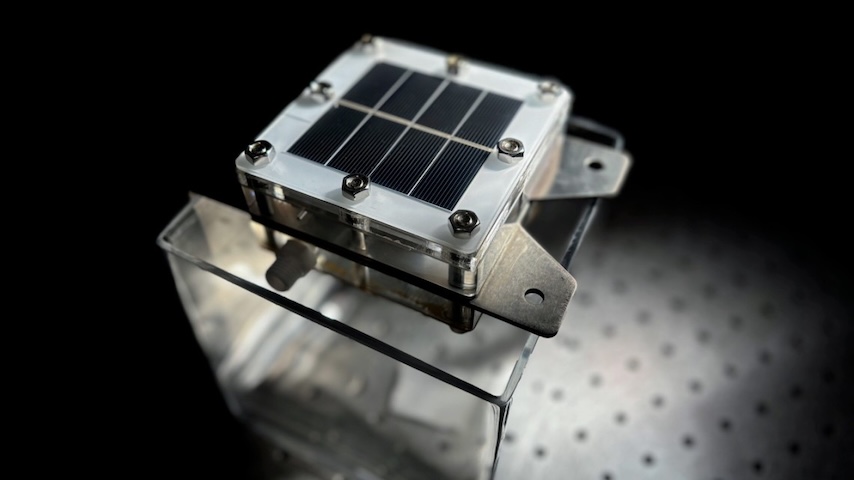

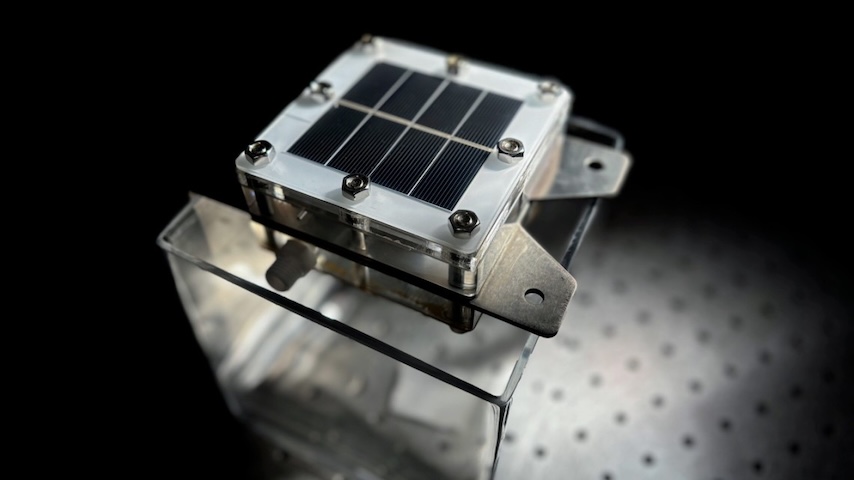

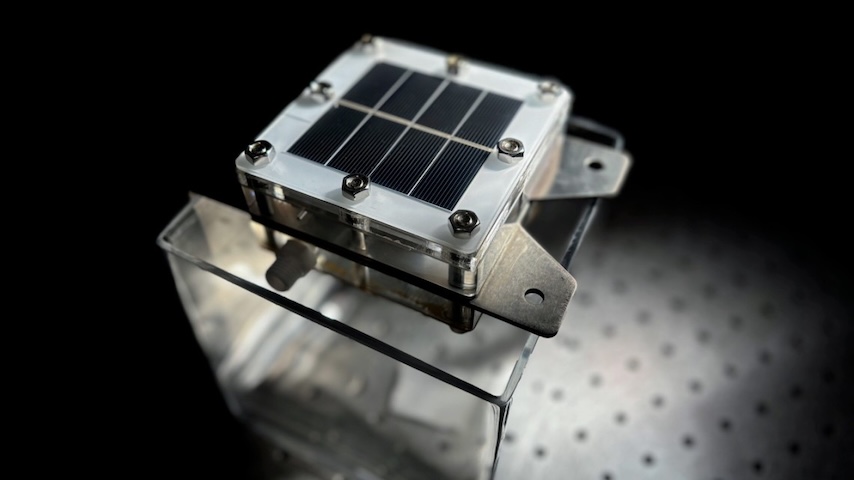

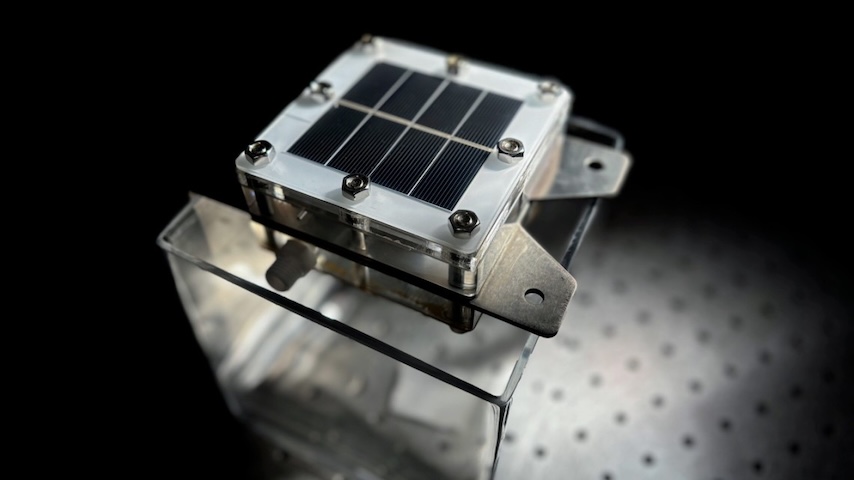

After building a 10-cm-by-10-cm prototype, the team tested it on a Boston rooftop using natural sunlight, wind, and humidity with untreated seawater. Over multiple days, the device produced one liter of water per hour, per square meter of solar panel, operating reliably without fouling.

Researchers tested the device with seawater salinity ranging from 3.5 percent to 10 percent and observed no crystallization, salt accumulation, or salinity buildup. Since the electrolyzer only used 20 to 30 percent of the solar energy, it processed less water than the device produced, leaving a surplus available for drinking. “On average, one square meter of the device yielded about five liters of drinking water per day, enough for one person, while also generating hydrogen,” Zhang explained.

Since the system uses off-the-shelf solar panels, evaporators, and electrolyzers, it's easy to scale as well. The researchers envision modular units that could combine to form larger hydrogen and water production farms.

Off-grid regions offer ideal deployment sites, where the device could generate both water and energy without external power. It converts solar energy into hydrogen, which users could store and later use to generate electricity at night through a fuel cell, while also producing drinking water for daily use. Existing solar farms could also adopt a system to capture and use waste heat.

Discover the Benefits of ASME Membership

By eliminating the need for electricity and clean water, two major cost drivers, the device significantly cuts green hydrogen production costs. Integrated antifouling design reduces maintenance, lowers operating expenses, and shortens the payback period to about 15 years. Aside from basic upkeep, hydrogen production costs less than $1 per kilogram. This breakthrough pushes costs down from $10 per kg to $1 per kg, aligning with the U.S. Department of Energy’s “1 1 1” goal: $1 per kilogram within one decade.

“The key innovation was eliminating reliance on external water sources for green hydrogen production. This addressed global water scarcity and reduced hydrogen production costs,” Zhang said. “By integrating all functions into a single, flexible system, rather than relying on centralized or multi-plant setups, we lowered costs further and enabled operation in both off-grid regions and existing infrastructure.”

Theoretically, producing one kilogram of hydrogen requires nine kilograms of water. In practice, the researchers found the ratio ranged from 20 to 30 kilograms of water per kilogram of hydrogen. With 2024’s global hydrogen demand near 100 million metric tons, expected to increase to 180 million metric tons by 2030, electrolysis at that scale would consume more drinking water annually than the entire global population.

As hydrogen demand continues to surge, technologies like this will play a critical role in accelerating the energy transition, while strengthening water security, reducing costs, and improving climate resilience.

Nicole Imeson is an engineer and writer in Calgary, Alta.

To develop the apparatus, the team tackled two major obstacles: seawater corrosion and waste heat loss. They designed the system to harness the full solar spectrum. High-energy light powers a photovoltaic panel to generate electricity. Meanwhile, waste heat and low-energy light powers a photothermal process. On the panel’s backside, a wicking evaporator passively pulls in seawater. The panel’s heat vaporizes water, leaving the concentrated brine behind.

“A siphon effect drove a gentle, continuous fluid flow through the evaporator, from inlet to outlet. This steady movement was strong enough to create a flushing action, effectively sweeping out the brine and carrying seawater through the system,” explained Lenan Zhang, assistant professor at Cornell’s Sibley School of Mechanical and Aerospace Engineering.

Water vapor condenses across a narrow gap directly onto the electrolyzer, which then uses electricity from the solar panel to split water into hydrogen and oxygen, collecting hydrogen for energy storage or use.

More for You: Microwaves Could Make for Greener Hydrogen

Evaporation cools the solar panel, enhancing electricity production, while the condensation process warms the electrolyzer, boosting hydrogen output. By combining solar energy, seawater evaporation, and electrolysis in one streamlined system, the device offers a scalable, sustainable way to produce green hydrogen and clean water, especially in off-grid or water-scarce regions.

After building a 10-cm-by-10-cm prototype, the team tested it on a Boston rooftop using natural sunlight, wind, and humidity with untreated seawater. Over multiple days, the device produced one liter of water per hour, per square meter of solar panel, operating reliably without fouling.

Researchers tested the device with seawater salinity ranging from 3.5 percent to 10 percent and observed no crystallization, salt accumulation, or salinity buildup. Since the electrolyzer only used 20 to 30 percent of the solar energy, it processed less water than the device produced, leaving a surplus available for drinking. “On average, one square meter of the device yielded about five liters of drinking water per day, enough for one person, while also generating hydrogen,” Zhang explained.

Since the system uses off-the-shelf solar panels, evaporators, and electrolyzers, it's easy to scale as well. The researchers envision modular units that could combine to form larger hydrogen and water production farms.

Off-grid regions offer ideal deployment sites, where the device could generate both water and energy without external power. It converts solar energy into hydrogen, which users could store and later use to generate electricity at night through a fuel cell, while also producing drinking water for daily use. Existing solar farms could also adopt a system to capture and use waste heat.

Discover the Benefits of ASME Membership

By eliminating the need for electricity and clean water, two major cost drivers, the device significantly cuts green hydrogen production costs. Integrated antifouling design reduces maintenance, lowers operating expenses, and shortens the payback period to about 15 years. Aside from basic upkeep, hydrogen production costs less than $1 per kilogram. This breakthrough pushes costs down from $10 per kg to $1 per kg, aligning with the U.S. Department of Energy’s “1 1 1” goal: $1 per kilogram within one decade.

“The key innovation was eliminating reliance on external water sources for green hydrogen production. This addressed global water scarcity and reduced hydrogen production costs,” Zhang said. “By integrating all functions into a single, flexible system, rather than relying on centralized or multi-plant setups, we lowered costs further and enabled operation in both off-grid regions and existing infrastructure.”

Theoretically, producing one kilogram of hydrogen requires nine kilograms of water. In practice, the researchers found the ratio ranged from 20 to 30 kilograms of water per kilogram of hydrogen. With 2024’s global hydrogen demand near 100 million metric tons, expected to increase to 180 million metric tons by 2030, electrolysis at that scale would consume more drinking water annually than the entire global population.

As hydrogen demand continues to surge, technologies like this will play a critical role in accelerating the energy transition, while strengthening water security, reducing costs, and improving climate resilience.

Nicole Imeson is an engineer and writer in Calgary, Alta.