A Feathery Fuel Cell

A Feathery Fuel Cell

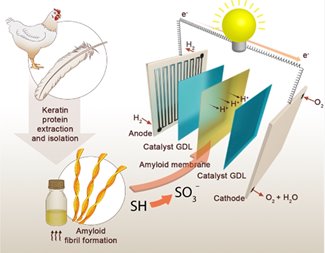

Chicken feathers are a waste product but are rich in keratin, which researchers have used to create an electricity-generating membrane for fuel cells.

Chicken feathers are ordinarily a waste product of the poultry industry and are normally incinerated for disposal. However, researchers at ETH Zurich, a public research university in Zürich, Switzerland, and Nanyang Technological University Singapore have teamed up to explore ways to use waste feathers to help create fuel cells. It could offer a cost-effective and sustainable material to replace existing components.

In their paper, "Renewable Energy from Livestock Waste Valorization: Amyloid -based Feather Keratin Fuel Cells," (ACS Applied Materials & Interfaces 2023), the team published findings and explained how they extracted keratin, a fibrous protein found in chicken feathers, to be used in a fuel cell. They then converted the keratin to ultra-thin fibers to make up a membrane. The membrane was then used in a fuel cell as a means of generating a voltage potential, which translates into electricity.

A fuel cell generates electricity from hydrogen and oxygen, releasing only heat and water. Within the configuration of a fuel cell is a membrane that is semi-permeable. Protons may pass through it, but electrons do not. Instead, the electrons are redirected to travel through an external circuit. Their path from a negative anode to a positive cathode produces an electrical current.

Conventional fuel cells use materials for a semipermeable membrane that are not of sustainable sources and do not biodegrade. Because of keratin's fibrous and durable structure, it may be used to create such a membrane. It exemplifies how materials that ordinarily were a waste product of no value may be put to work as a sustainable source for a fuel cell membrane.

Raffaele Mezzenga, a professor of food and soft materials at ETH Zurich, said chicken feathers are very rich in keratin; the protein comprises more than 90 percent of the feathers.

Become a Member: How to Join ASME

"We extract the keratin, turn [it] into keratin nanofibrils [also called amyloid fibrils], prepare membranes made thereof, and then we modify them to become proton donor membranes, and hence possess the main feature of fuel cell membranes," he said.

"Keratin is well suited for the creation of this proton donor membrane. "Keratin is rich in cysteine, an essential amino acid, which contains sulfur and can be modified into a group capable of releasing protons," explained Mezzenga. "This is the main key aspect of proton conductive membranes in fuel cells and hence, it was precisely the high content of keratin in chicken feathers and the special composition of keratin to guide us in the right direction."

The main significance of using keratin in this way is to demonstrate an effective use of a waste product, which has had little value. The work could create a whole new value chain for food waste products such as chicken feathers, believe the researchers.

"The main point is that we have demonstrated that it is possible to convert 30 to 40 megatons of food chain side streams, that is the chicken feathers in this case, [that typically] endiup in incineration and the generation of carbon dioxide, but also sulfur dioxide, a highly toxic gas, into the key enabler of membranes for the production of clean energy, generating only electricity and water and some heat," Mezzenga said. "The significance lies precisely in the possibility of converting [carbon dioxide] emissions into carbon neutral clean energy technologies. The benefit may be for the entire population, not only poultry providers or users of this technology, as we all share the same planet."

More for You: Bolsterting Batteries with Zinc

While the research puts a byproduct of the poultry industry to good use, there's still work to be done to refine the application and the concept of using keratin.

The researchers must now explore just how durable their keratin membrane is and modify it as required. The team has filed a joint patent with other stakeholders of the research and are seeking partners to further develop this technology to successfully bring it to market at a greater scale.

"We are working on it and we are confident this can be done with the help and synergy with the right people," Mezzenga said. "We are right now starting to look for joint ventures to make this become not only a beautiful concept but a disruptive technology."

Jim Romeo is an independent writer in Chesapeake, Va.

In their paper, "Renewable Energy from Livestock Waste Valorization: Amyloid -based Feather Keratin Fuel Cells," (ACS Applied Materials & Interfaces 2023), the team published findings and explained how they extracted keratin, a fibrous protein found in chicken feathers, to be used in a fuel cell. They then converted the keratin to ultra-thin fibers to make up a membrane. The membrane was then used in a fuel cell as a means of generating a voltage potential, which translates into electricity.

A fuel cell generates electricity from hydrogen and oxygen, releasing only heat and water. Within the configuration of a fuel cell is a membrane that is semi-permeable. Protons may pass through it, but electrons do not. Instead, the electrons are redirected to travel through an external circuit. Their path from a negative anode to a positive cathode produces an electrical current.

Conventional fuel cells use materials for a semipermeable membrane that are not of sustainable sources and do not biodegrade. Because of keratin's fibrous and durable structure, it may be used to create such a membrane. It exemplifies how materials that ordinarily were a waste product of no value may be put to work as a sustainable source for a fuel cell membrane.

Raffaele Mezzenga, a professor of food and soft materials at ETH Zurich, said chicken feathers are very rich in keratin; the protein comprises more than 90 percent of the feathers.

Become a Member: How to Join ASME

"We extract the keratin, turn [it] into keratin nanofibrils [also called amyloid fibrils], prepare membranes made thereof, and then we modify them to become proton donor membranes, and hence possess the main feature of fuel cell membranes," he said.

"Keratin is well suited for the creation of this proton donor membrane. "Keratin is rich in cysteine, an essential amino acid, which contains sulfur and can be modified into a group capable of releasing protons," explained Mezzenga. "This is the main key aspect of proton conductive membranes in fuel cells and hence, it was precisely the high content of keratin in chicken feathers and the special composition of keratin to guide us in the right direction."

The main significance of using keratin in this way is to demonstrate an effective use of a waste product, which has had little value. The work could create a whole new value chain for food waste products such as chicken feathers, believe the researchers.

"The main point is that we have demonstrated that it is possible to convert 30 to 40 megatons of food chain side streams, that is the chicken feathers in this case, [that typically] endiup in incineration and the generation of carbon dioxide, but also sulfur dioxide, a highly toxic gas, into the key enabler of membranes for the production of clean energy, generating only electricity and water and some heat," Mezzenga said. "The significance lies precisely in the possibility of converting [carbon dioxide] emissions into carbon neutral clean energy technologies. The benefit may be for the entire population, not only poultry providers or users of this technology, as we all share the same planet."

More for You: Bolsterting Batteries with Zinc

While the research puts a byproduct of the poultry industry to good use, there's still work to be done to refine the application and the concept of using keratin.

The researchers must now explore just how durable their keratin membrane is and modify it as required. The team has filed a joint patent with other stakeholders of the research and are seeking partners to further develop this technology to successfully bring it to market at a greater scale.

"We are working on it and we are confident this can be done with the help and synergy with the right people," Mezzenga said. "We are right now starting to look for joint ventures to make this become not only a beautiful concept but a disruptive technology."

Jim Romeo is an independent writer in Chesapeake, Va.