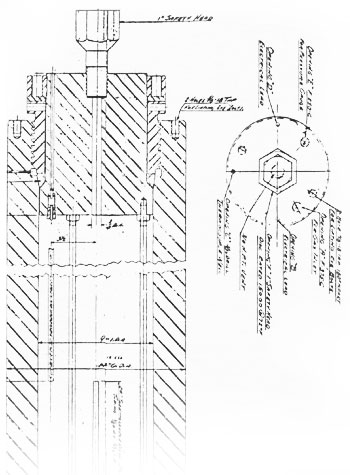

#103 First Hot Isostatic Processing Vessels*

1956

Early examples of fabrication vessels using gas pressure and temperature to produce advanced alloy and ceramic products

Today HIP is used in industry worldwide to produce advanced alloy and ceramic products, particularly complex-shaped parts and products. HIP uses gas pressure and temperature to fabricate parts and products, bond and densify materials, consolidate powders, and heal defects. Developed in order to bond components of small Zircaloy-clad pin-type nuclear fuel elements, the process was soon applied to compact powders for use in tool steel, superalloys for jet engines, and materials for space applications. The strict dimensional control provided in a HIP vessel makes it useful as a manufacturing technique for near-net-shape processing and other complex fabrications.

Landmark Location

Battelle Memorial Institute

505 King Avenue

Columbus, OH 43201-2693

Visiting Info

* Indicates that item has survived, but is not on display.

Ceremony Notes

April 1985