Practical Welding Technology

Course Type:

Product Number:

Credits:

Language:

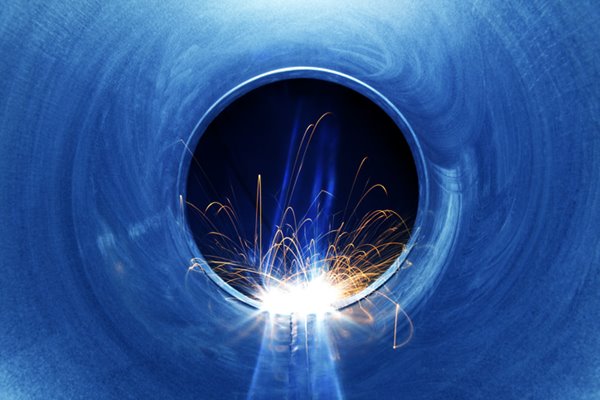

Understand welding technology, including applicable codes and standards, principles, procedures, symbols, material selection and preheat.

This Standard was last reviewed and reaffirmed in {{activeProduct.ReaffirmationYear}}. Therefore this version remains in effect.

{{activeProduct.DisplayTitle}}

Digital products are restricted to one per purchase.

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

*Excluding Lite Members

Final invoices will include applicable sales and use tax.

Print or Share

Get papers online in the ASME Digital Collection

Sorry, we only have available spots for this course. Would you like to add those to your cart?