A Future Engineer’s Take: A Transparent Aerogel

A Future Engineer’s Take: A Transparent Aerogel

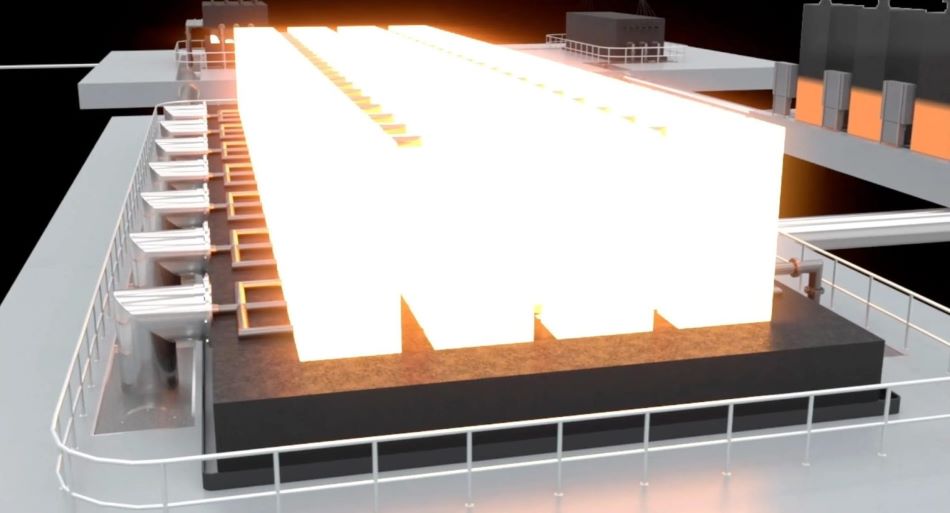

This week, I decided to do something a little different. Instead of going to an event, I read a very interesting article about material that was developed by MIT and could be part of creating much more powerful solar panels. This material is called an aerogel. Aerogels have already existed, but the one that MIT developed is extremely transparent, allowing sunlight through while trapping heat. This allows it to capture huge amounts of solar energy. For reference, the device was placed outside when the ambient temperature was 0 degrees Celsius and, just from sunlight, it reached 220 degrees Celsius. Lin Zhao, who worked on the project, said that “The material we use to increase the temperature acts like the Earth’s atmosphere does to provide insulation, but this is an extreme example of it.”

After I read this article, I was extremely interested in learning more about this material and the process by which it was created. To that end, I reached out to the research team and Lin answered some of my questions.

For those unfamiliar with the properties of aerogels, could you describe them briefly? Is this one durable and resilient enough to withstand industrial applications?

Aerogel is a class of highly porous materials with pore and particle size in the nanometer range. The most common aerogel is made of silica, the same material as glass. It has high porosity and extremely low thermal conductivity, which enable its current application as a lightweight thermal insulation material. The transparent silica aerogel developed in this work adds glass-level optical transparency to conventional silica aerogel while maintains its other properties. The mechanical strength and durability of the transparent aerogel are on par with its conventional counterpart. In industrial applications, such as in a solar thermal collector, the transparent aerogel needs to be protected in an enclosure to shield it from harmful outdoor conditions. With proper protection, the aerogel can survive even under harsh conditions, as demonstrated by the aerogel insulations for underwater pipelines.

Is this aerogel dried in a way that makes it hydrophilic or hydrophobic?

The aerogel is hydrophilic after the drying step in the current process. The aerogel can also be made hydrophobic with an additional step before drying. For solar thermal collectors, as the aerogel will be placed in the sealed collector enclosure, the additional hydrophobic treatment is not necessary.

What were some of the challenges that you faced when making the aerogel this transparent? How did you overcome them?

The key challenge of achieving high optical transparency is to minimize the particle and pore size in the aerogel without affecting its other thermal and mechanical properties. In order to overcome this challenge, we did a thorough parametric sweep of the synthesis recipe and narrowed down to the one that gives the optimal transparency. In the meantime, other parts of the synthesis procedure such as the aging and drying step, have also been optimized to minimize the chance of crack and imperfection in the fabricated monolithic aerogel.

The article mentions that the materials needed to make the aerogel are abundant, but the drying process is expensive due to the need for specialized tech. Is there progress being made on reducing this cost?

The drying step – critical point drying (CPD) with CO2 is indeed a significant contributor to the overall cost of the aerogel. However, the CPD technique has been proved economically viable as current aerogel companies are using large-scale CPD to produce aerogel. In addition, other low-cost drying techniques, such as ambient drying, are currently under investigation.

Given that this aerogel is created in a batch process rather than a continuous one, what uses for this product are the most economically viable?

The batch process itself will not limit the application of the aerogel as a product. However, it requires high capital investment to scale up the production line. Potential beachhead markets of the aerogel include solar thermal collectors for medical sterilizations, adsorption chillers, process steam for the food industry, etc.

Are there any non-solar applications that are being looked at for this material?

The transparent aerogel can also be used in high-performance windows as a spacer material between two panes of glass in a double-pane window. With the added aerogel layer, the double-pane window can have similar performance of a triple-pane window with a lower cost. A graduate student in our group working on this application has shown very promising results for the transparent aerogel in the window industry.

Thanks to Lin for answering my questions! If you want to learn more about this research, you can do so here: http://news.mit.edu/2019/aerogel-passive-heat-sunlight-0702.

Unfortunately, my time with ASME this summer is coming to a close. I’ll be writing one last article next week, which I am looking forward to! Like last week, I’m not sure what it will be about. Hopefully the topic is as unique and engaging as this one!

After I read this article, I was extremely interested in learning more about this material and the process by which it was created. To that end, I reached out to the research team and Lin answered some of my questions.

For those unfamiliar with the properties of aerogels, could you describe them briefly? Is this one durable and resilient enough to withstand industrial applications?

Aerogel is a class of highly porous materials with pore and particle size in the nanometer range. The most common aerogel is made of silica, the same material as glass. It has high porosity and extremely low thermal conductivity, which enable its current application as a lightweight thermal insulation material. The transparent silica aerogel developed in this work adds glass-level optical transparency to conventional silica aerogel while maintains its other properties. The mechanical strength and durability of the transparent aerogel are on par with its conventional counterpart. In industrial applications, such as in a solar thermal collector, the transparent aerogel needs to be protected in an enclosure to shield it from harmful outdoor conditions. With proper protection, the aerogel can survive even under harsh conditions, as demonstrated by the aerogel insulations for underwater pipelines.

Is this aerogel dried in a way that makes it hydrophilic or hydrophobic?

The aerogel is hydrophilic after the drying step in the current process. The aerogel can also be made hydrophobic with an additional step before drying. For solar thermal collectors, as the aerogel will be placed in the sealed collector enclosure, the additional hydrophobic treatment is not necessary.

What were some of the challenges that you faced when making the aerogel this transparent? How did you overcome them?

The key challenge of achieving high optical transparency is to minimize the particle and pore size in the aerogel without affecting its other thermal and mechanical properties. In order to overcome this challenge, we did a thorough parametric sweep of the synthesis recipe and narrowed down to the one that gives the optimal transparency. In the meantime, other parts of the synthesis procedure such as the aging and drying step, have also been optimized to minimize the chance of crack and imperfection in the fabricated monolithic aerogel.

The article mentions that the materials needed to make the aerogel are abundant, but the drying process is expensive due to the need for specialized tech. Is there progress being made on reducing this cost?

The drying step – critical point drying (CPD) with CO2 is indeed a significant contributor to the overall cost of the aerogel. However, the CPD technique has been proved economically viable as current aerogel companies are using large-scale CPD to produce aerogel. In addition, other low-cost drying techniques, such as ambient drying, are currently under investigation.

Given that this aerogel is created in a batch process rather than a continuous one, what uses for this product are the most economically viable?

The batch process itself will not limit the application of the aerogel as a product. However, it requires high capital investment to scale up the production line. Potential beachhead markets of the aerogel include solar thermal collectors for medical sterilizations, adsorption chillers, process steam for the food industry, etc.

Are there any non-solar applications that are being looked at for this material?

The transparent aerogel can also be used in high-performance windows as a spacer material between two panes of glass in a double-pane window. With the added aerogel layer, the double-pane window can have similar performance of a triple-pane window with a lower cost. A graduate student in our group working on this application has shown very promising results for the transparent aerogel in the window industry.

Thanks to Lin for answering my questions! If you want to learn more about this research, you can do so here: http://news.mit.edu/2019/aerogel-passive-heat-sunlight-0702.

Unfortunately, my time with ASME this summer is coming to a close. I’ll be writing one last article next week, which I am looking forward to! Like last week, I’m not sure what it will be about. Hopefully the topic is as unique and engaging as this one!