2020 Updated U.S. Robotics Roadmap Released by Consortium of Universities

2020 Updated U.S. Robotics Roadmap Released by Consortium of Universities

At this year’s RIA Robotics Week, Henrik Christensen, Director of the Contextual Robotics Institute at the University of California San Diego, provided a keynote address titled, "Wha's Next for Robotics: A Look at the U.S. Robotics Roadmap." The 2020 version of the robotics roadmap was just released in conjunction with the event, outlining specific societal drivers and what research is still needed to address specific challenges. The report outlines main findings, calling attention to the growth see in the utilization of robotics in recent years, specifically in relation to robotics in manufacturing environments, where collaborative robotics have enabled huge growth by reducing physical barriers between robots and humans.

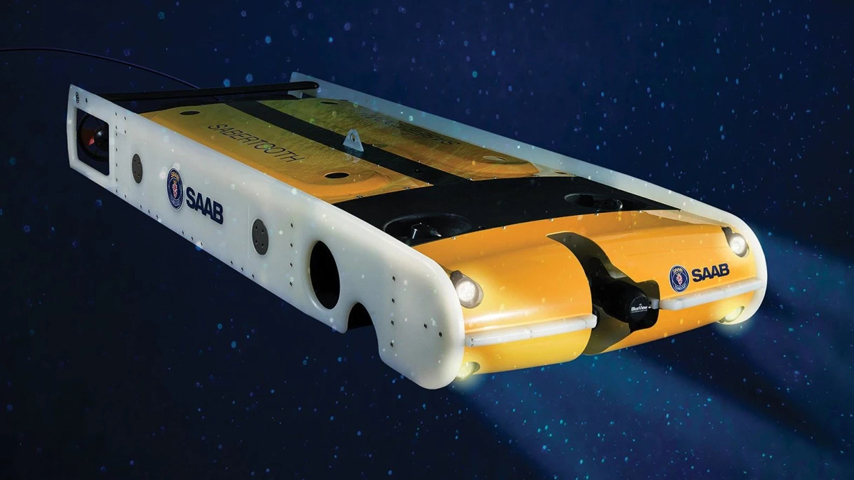

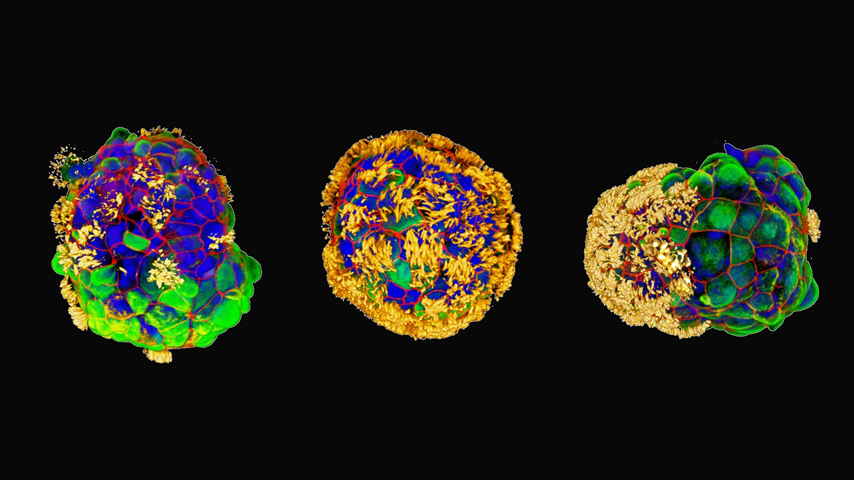

The roadmap lists seven societal drivers to consider when planning for the future of U.S. robotics: manufacturing, logistics and e-commerce, transportation, quality of life, clinical healthcare, food supply, and security and rescue. Many of these drivers overlap specifically with key areas named by the ASME Public Policy Task Force in it’s recent white paper on Robotics & COVID-19: How Robotic Technologies are Critical in Getting America Up and Running in The Age of the COVID-19 Pandemic. The roadmap also dedicates a small section to COVID-19 specifically and how it is affect the robotics sector, or the societal drivers of the robotics sector. Here, all five of the major areas where robotics can be useful in combating COVID-19 outlined by ASME are covered as well: deep cleaning, rapid manufacturing, logistics, healthcare, and telepresence.

The new roadmap also touches on many of the same goals that ASME has for the robotics industry, which are outlined in the ASME General Position Paper on Accelerating U.S. Robotics for American Prosperity and Security. The emphasis on collaborative robotics in manufacturing environments is especially poignant as the largest application of robotics in the U.S. has been in manufacturing, with a resulting dramatic improvement in productivity and competitiveness. As stated in the roadmap: “In the US the industrial robotics market has grown 10+% every year and the market has so far seen less than 10% penetration. We are thus far away for full automation of our factories.” At first, this statement may be cause for concern, as robots continue to find work on the factory floor. In reality however, the roadmap goes on to point out that, “Robots keep U.S. manufacturing competitive by allowing them to improve product quality, increase productivity, get products to market faster and lowering the overall costs. As a result, manufacturing jobs are growing as more robots are adopted in the U.S. Since 2010, some 180,000 robots have been shipped to U.S. companies during the same period 1.2 million new manufacturing jobs have been created. At the same time, robots are making the workplace safer by performing dangerous tasks that people should not be doing.”

Finally, the roadmap goes on to outline specific recommendations, which again fall inline with those offered by ASME in its own robotics public policy papers, including:

The roadmap lists seven societal drivers to consider when planning for the future of U.S. robotics: manufacturing, logistics and e-commerce, transportation, quality of life, clinical healthcare, food supply, and security and rescue. Many of these drivers overlap specifically with key areas named by the ASME Public Policy Task Force in it’s recent white paper on Robotics & COVID-19: How Robotic Technologies are Critical in Getting America Up and Running in The Age of the COVID-19 Pandemic. The roadmap also dedicates a small section to COVID-19 specifically and how it is affect the robotics sector, or the societal drivers of the robotics sector. Here, all five of the major areas where robotics can be useful in combating COVID-19 outlined by ASME are covered as well: deep cleaning, rapid manufacturing, logistics, healthcare, and telepresence.

The new roadmap also touches on many of the same goals that ASME has for the robotics industry, which are outlined in the ASME General Position Paper on Accelerating U.S. Robotics for American Prosperity and Security. The emphasis on collaborative robotics in manufacturing environments is especially poignant as the largest application of robotics in the U.S. has been in manufacturing, with a resulting dramatic improvement in productivity and competitiveness. As stated in the roadmap: “In the US the industrial robotics market has grown 10+% every year and the market has so far seen less than 10% penetration. We are thus far away for full automation of our factories.” At first, this statement may be cause for concern, as robots continue to find work on the factory floor. In reality however, the roadmap goes on to point out that, “Robots keep U.S. manufacturing competitive by allowing them to improve product quality, increase productivity, get products to market faster and lowering the overall costs. As a result, manufacturing jobs are growing as more robots are adopted in the U.S. Since 2010, some 180,000 robots have been shipped to U.S. companies during the same period 1.2 million new manufacturing jobs have been created. At the same time, robots are making the workplace safer by performing dangerous tasks that people should not be doing.”

Finally, the roadmap goes on to outline specific recommendations, which again fall inline with those offered by ASME in its own robotics public policy papers, including:

- Greater expertise in government. In order to foster innovation in robotics, maximize its potential for social good, and minimize its potential for harm, government at all levels should continue to accrue expertise in cyber-physical systems.

- Support of interdisciplinary research in government and academia. Few issues in robotics, or any other context, are amendable to resolution by reference to any one discipline. Government and academia should actively work to support and incentivize interdisciplinary research and breakdown siloes between expertise.

- Removal of research barriers. As alluded to above, independent researchers should be assured that efforts to understand and validate systems for the purpose of accountability and safety do not carry legal risk under existing law or doctrine.