Targeting China’s Mountains of Sludge

Targeting China’s Mountains of Sludge

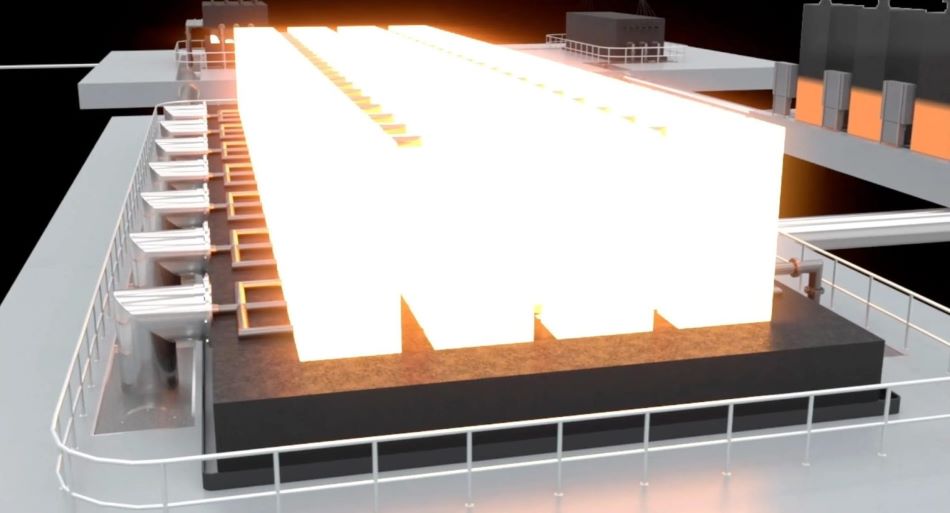

China has been burying itself under heaps of toxic sludge, but one startup may have a technological solution. Innov8tia Environmental Engineering, Ningbo, China, has developed a microwave pyrolysis reactor that decontaminates industrial sludge, converting it into valuable gases and chemicals.

China’s sewage and industrial sludge has contaminated water and soil with heavy metals, pesticides, and pathogens. Some of the waste goes to landfills that will accept it, but illegal dumping has been easy and cheap.

“To dispose of 500 tons of toxic sludge in the south China city of Guangzhou, all you need is a hired boat and a little money for petrol,” Yang Dazheng and colleagues write on Chinadialogue.net.

There may be change on the horizon after a nationwide government crackdown on polluters in late 2017 that swept up 12,000 officials and fined 18,000 companies. The Dafeng Pesticide Factory in Yancheng City, 250 km north of Shanghai, closed during a surprise inspection; the company then turned to Innov8tia for help processing its sludge.

For You: 5 Reasons for Engineers to Give Back

This is the largest, and we think only, microwave pyrolysis industrial sludge treatment system currently in operation in the world. Seth Knutson, Innov8tia Environmental Engineering

Test runs of two scaled down versions of Innov8tia’s reactors found that they could convert 30 percent to 35 percent of a Dafeng sludge sample to char, and 65 percent to 70 percent into gas, most of which was hydrogen and carbon monoxide.

Both gases are valuable. Hydrogen is used in the petroleum and chemical industries and as a coolant, and carbon monoxideis used in chemical manufacturing, meat packing, medicine, and even lasers.

The process also yields other useful materials, including carbon nanotubes and more than 70 chemicals (levoglucosenone, furfural, phenolic compounds, 3-aminopiperidin-2-one, Dallose, cresols, vanillin, and others) that value at $1,200 to $250,000 per ton.

The process is more efficient than traditional pyrolysis at harvesting materials from sludge, and it generates more energy than it requires.

The three-person Innov8tia team graduated from the Vatican’s Laudato Si Accelerator in December 2017 and returned home with a $100,000 grant.

Now the team has moved into a 530-square-meterwarehouse in the Ningbo National Hi-Tech Zone, a government-operated technology park. Their neighbors are 30 other startups, all better funded than they are, says Seth Knutson, one of the co-founders.

“Our current reactor system, capable of treating 20 to 40 kilogramsof sludge per hour, is up and running in this facility, although it’s essentially an empty warehouse right now,” Knutson says. “This is the largest, and we think only, microwave pyrolysis industrial sludge treatment system currently in operation in the world. Innov8tia should be the first company in the world to offer microwave pyrolysis systems for industrial sludge treatment.”

Another co-founder, chemical engineer Kaiqi Shi, developed the microwave pyrolysis technology while studying at the University of Nottingham’s China campus. Shi developed a self-cleaning nickel catalyst that converts more of the sludge into gases and less into char.

Thus, the microwave process harvests more materials from sludge and requires less energy than traditional pyrolysis. Innov8tia’s first commercial system can treat 500 kg of sludge per day.

The technology has been independently certified by a group at the Chinese Academy of Sciences. The team’s patent won an Innovation Award from the government of China, and the prototype was independently verified by a group of industry experts.

One of Innov8tia’s first jobs in its new headquarters is to test sludge samples sent from a leading international environmental services provider, a relationship forged in Rome during the accelerator. No agreements have been signed, yet, and the company will remain anonymous until a possible future public announcement.

In the meantime, a technology like Innov8tia’s has a vast market in China.

The Chinese government has pledged to clean up the country’s polluting industries, and companies may be seeking legal means of treating their waste.

Rob Goodier is managing editor at Engineering for Change. For more articles on global development visit www.engineeringforchange.org

Read More:

System Helps Self-driving Cars See in Fog

Energy Storage Smooths the Duck Curve

Creative Approach to Engineering Improves Grades