Living in the Material World

Living in the Material World

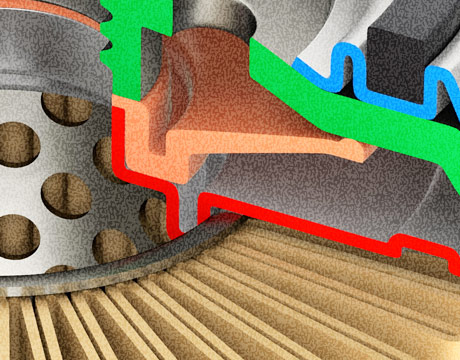

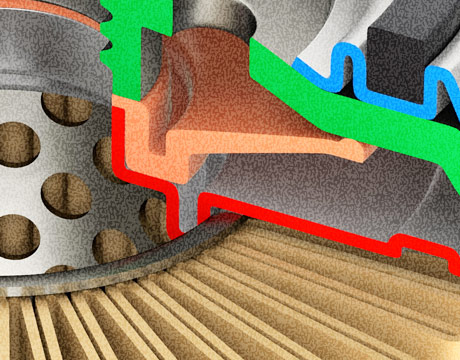

Just as clothes make the man, materials make the part. When a material is perfectly suited to a design, the resulting structure holds up under heavy use, springs back into shape when bent, and handles high temperatures without buckling. It does exactly what we ask.

Yet engineers often fail to select the ideal material for their designs. This is not because they are lazy or do not appreciate the difference materials can make. Rather, it is because their CAD systems often push them in other directions.

CAD systems are essentially tools optimized for just one job, design. Only after engineers have completed their CAD models do they input the materials that give those designs their physical (and other) properties. But how do they know if they have selected the best material for the job? Or whether switching to a better but unfamiliar material might enable them to improve their design?

This is an important consideration, because for products to reach the next level of performance, materials need to become part of the design process itself, contends Yan Wang, an associate professor of computer-aided engineering and design at Georgia Tech.

“Materials discovery and integration is the key to the new products we want to make,” Wang said. His research has explored that issue since 2000. It is a task CAD vendors are only beginning to tackle today.

Materials Selection Now

To appreciate how Wang and others want to change design, consider how engineers create products today. Essentially, they start with a function, then design structures and geometries to achieve the desired performance. After they complete the design they choose a material. Their goal is to pick one whose strength, durability, hardness, flexibility, thermal, and other properties best match the part’s function.

Only then, drawing on simulation tools like finite element analysis (FEA), can they analyze the design’s performance to see if they chose the right material.

This is an iterative and time-consuming process. Based on the limitations of the material, engineers might go back and tweak elements of their design. If those design changes make the part too large, heavy, or expensive, they might specify a different material. Back and forth they go, redesigning and simulating. Eventually, they reach an optimized design—or, to be realistic, a compromise they can live with.

Part of the problem is that most designers work from a very limited portfolio of materials, said John Downing, a technical communications specialist at Granta Design in Cambridge, England. “Designers rely on supplier recommendations or simply reuse what they have used before,” he said.

Granta wants to expand their options. It does this by providing databases of materials and their properties, sometimes called libraries, that engineers can integrate into their CAD systems.

This starts with CES Selector, a stand-alone library of material property data that helps engineers screen materials based on design objectives and constraints. These criteria include not only materials properties, but also processing, economic, environmental, and other engineering constraints. Granta helps engineers wade through this data by graphically plotting these trade-offs, so engineers can see how the candidates measure up against the competing objectives of the application.

The tool is useful for identifying potential materials during the conceptual design phase and when searching for a replacement for a material that is not working out, Downing said.

Toward Integration

Although CES is an independent software program, it works with Granta’s MI:Materials Gateway, an app designed to work within many CAD systems as well as some simulation and analysis software. The app enables engineers to create databases that combine the Granta data library with their own in-house materials database, and to narrow down choices by searching for properties within those materials, Downing said.

Having a materials library is a good start. In fact, for many engineers who make products for applications whose demands are well-characterized, it is probably enough. But engineers who want to move beyond the usual suspects may need something more. They may want to combine materials to achieve very specific performance goals, or perhaps design structural materials themselves.

While there is not yet an app for that—at least one fully integrated with CAD—several developers are moving in that direction.

One group of developers might come as a surprise: 3-D printer developers. Their customers often complain about their narrow range of materials choices. Yet additive manufacturing has become a hotbed of materials-design innovation. It gives engineers a way to combine polymers and reinforcing fibers, and even polymers and metals (to make circuit boards).

The MultiFab printer developed by MIT’s Science and Artificial Intelligence Lab represents the extreme edge of this research. It enables engineers to print multiple materials at once and build objects whose segments have different properties, said Javier E. Ramos, a former researcher with the lab and a co-founder of Inkbit, a Cambridge, Mass., company that seeks to commercialize the technology.

In fact, MIT’s Foundry software enables MultiFab to control materials microstructures in ways that determine the material’s structural properties. It is one way to achieve performance that was not possible before, said Kiril Vidimce, an MIT graduate student who helped create Foundry. The software, he said, is “Photoshop for 3-D materials.”

Hod Lipson, director of the Creative Machines Lab at Columbia University, calls these intimately entwined materials “metamaterials.” The term is often used to describe materials that are not found in nature. While most materials used in 3-D printing are not natural to begin with, playing with their microstructures endows them with very different properties than their starting forms. Lipson is currently creating a database of such materials and investigating how to predict their properties more accurately.

Dassault Systèmes, like many large purveyors of engineering software, has made no secret of its desire to create a soup-to-nuts buffet of engineering software tools. The company is best known for its SolidWorks and CATIA CAD programs and Simulia simulation and analysis program. Materials simulation is also an important part of its plans.

In 2014, Dassault bought Accelrys, a company that made software to help biochemists and chemical engineers understand and manufacture molecules used in pharmaceuticals. Dassault promptly renamed the business Biovia, and improved its materials simulation capabilities for structural materials.

Biovia’s Materials Studio works a lot like the FEA tools mechanical engineers use to simulate designs. Just as engineers can see how a bracket or rotating part will affect the performance of a final product, Materials Studio shows how changes to the molecules and crystals that make up a material will determine the behavior of the bulk materials used to design structures.

To showcase how this works, Biovia researchers used Materials Studio to study how aluminum absorbs hydrogen. Aluminum is a promising candidate for storing hydrogen in fuel cells, said Alexander Goldberg, who was involved in the studies. By simulating interactions with hydrogen atoms and molecules, the researchers identified the aluminum clusters, nanowires, and crystals best suited for storage. The research will help engineers design structures that store more hydrogen at lower cost in new fuel cells.

This approach, modeling and simulating materials behavior at the smallest scales and using the information to predict the behavior of bulk materials, is called multiscale modeling. Several companies, including Toyota, Samsung, Boeing, and other aerospace and energy companies have bought into the concept. They now use Biovia to design new materials and simulate how they behave in engineering applications, Biovia CEO Max Carnecchia said.

Materials scientists have used simulation tools to do similar analyses in the past, but those programs were difficult to use. Biovia hopes to simplify the process and broaden the number of people who can use it. Ultimately, Dassault hopes to incorporate materials simulation into such engineering tools as CATIA, SolidWorks, and Simulia.

“This offers us an opportunity to substantially expand the range of what is possible,” Carnecchia said. “These joint solutions are needed to solve the most difficult problems in energy sustainability, resource utilization, and urban planning.”

Carnecchia’s boss, Dassault CEO Bernard Charles, reaffirms those thoughts. The most sophisticated designers are “moving toward using material as a variable, not a constraint,” he said. “And to do so, the ability to manage product information at the molecular level in a scalable manner is essential.”

That is Dassault’s vision. Clearly, most engineers will never need those advanced properties, and many of their employers will not have the means to create such unusual material variants. But others might.

It is probably too soon to determine if this technology will be adopted and used widely, said Marc Halpern, a vice president at technology research firm Gartner who follows product lifecycle management software.

After all, linking materials simulation with CAD modeling in ways that are useful to engineers is a big challenge. It is a problem Georgia Tech’s Wang has been working on for the past 17 years.

Part of CAD

Wang and his team are looking for ways to enable engineers to design a part and the materials that comprise it at the same time, within a single software application.

The system Wang envisions would work something like a combination of CAD and FEA, but with one key difference. Today, CAD-FEA systems enable engineers to test structures as they design them, then play with materials and design to see what works best.

Wang’s approach would give engineers tools to customize those materials at the microscale and give them just the right properties for the design. Engineers might, for example, start with a polymer that is close to what they want, then change its porosity and the size distribution of its pores to reduce mass and increase electrical resistance. Or they could alter the ratio of crystalline phases in a superalloy to strengthen it at high temperatures.

By integrating this into CAD design systems, engineers could alter materials at the microscale to achieve specific physical properties needed for the shapes and structures they design at the macroscale, Wang said.

“What we’re envisioning is a way for engineers to define their own materials rather than use those already discovered,” Wang said. “In this way, design engineers will be able to customize materials to their design in much the same way they select and change part geometries today.

“They’ll be able to simulate the product with the selected geometries and materials in an all-in-one package, and create new materials while they are designing new products,” he said.

This would truly make materials one of the top considerations within the design cycle, Wang added.

Jean-Bernard Bluntzer, an associate professor of mechanical engineering and design at University of Technology of Belfort-Montbeliard in France, wants to go even further. His design approach, Design for Materials, calls for using materials selection to help define CAD design allowables.

“The main objective of this new approach,” he explained in a paper given at the 2016 Conference of the International Academy for Production Engineering, “is to allow the product geometry and structure to be driven by the material specifications with the help of new CAD tools. The morphology of the product should emerge from a primarily material-driven design process.”

Bluntzer’s concept calls for engineers to choose a family of materials, say plastics, when defining the part. Then, as they design, they’d drill down further, to define the type of plastic to be used. Finally, in the last engineering design step in which materials are ordinarily assigned, the engineer would refine the material even further, perhaps by choosing a reinforcement or filler material, Bluntzer wrote.

“Using this approach, the morphology of the product is driven by material requirements,” he said. “Therefore, this approach allows the designer to design different product forms according to the material requirements of clients.”

Clearly, materials and structure cannot exist without one another. Designers know this, and they often spend quite a bit of time doing iterative materials selection once they complete their design.

Materials-design integration would allow them to do this more fluidly. The tools Wang, Bluntzer, and others want to build would enable design to inform materials selection while materials inform design possibilities, all within a single process.

That process might give engineers and material scientists a way to do something they do not: communicate with one another. “There’s a way to bring both of them together, and both communities are starting to see this,” Wang said.

The result might be a new wave of innovation. Using a single system to combine materials specification with product design could unleash new types of materials and material combinations, and surprising structures with properties never seen before, Wang said.ME

Jean Thilmany is an independent writer based in St. Paul, Minn.

Read more articles from Mechanical Engineering Magazine.