Advanced Robotics in Manufacturing Congressional Briefing Summary

Advanced Robotics in Manufacturing Congressional Briefing Summary

On December 13, 2016, a Congressional Briefing on “Advanced Robotics in Manufacturing” was held in the Senate. Moderating the panel was Chuck Thorpe, Senior Vice President and Provost of Clarkson University and Co-Chair of the ASME Robotics Public Policy Task Force.

The four panelists included:

- Howie Choset, Carnegie Mellon University, Professor of Robotics; Medrobotics, Inc., Co-Founder

- Larry Sweet, Georgia Institute of Technology, IRIM Associate Director of Technology Transition and Professor of the Practice in Robotics

- Erik Nieves, PlusOne Robotics, Founder and CEO

- Michael Dudzik, IQM, President

The briefing began with opening remarks delivered by Senator Chris Coons, a Co-Chair of the Senate Competitiveness Caucus. Senator Coons posed a few questions to the panelists to encourage discussion around how we can rise above the challenges facing the industry today, such as: What does the future of employment in the manufacturing industry look like and what does robotics in manufacturing mean for manufacturing jobs? How do we deal with cyber security as more elements of our manufacturing infrastructure rely on robotics? And how do we help small and medium-sized companies succeed with, and adapt to, new technologies? The Senator announced that he believes we have reason for optimism moving forward, citing the Manufacturing USA and Manufacturing Extension Partnerships (MEP) initiatives as opportunities for increased success in the coming year.

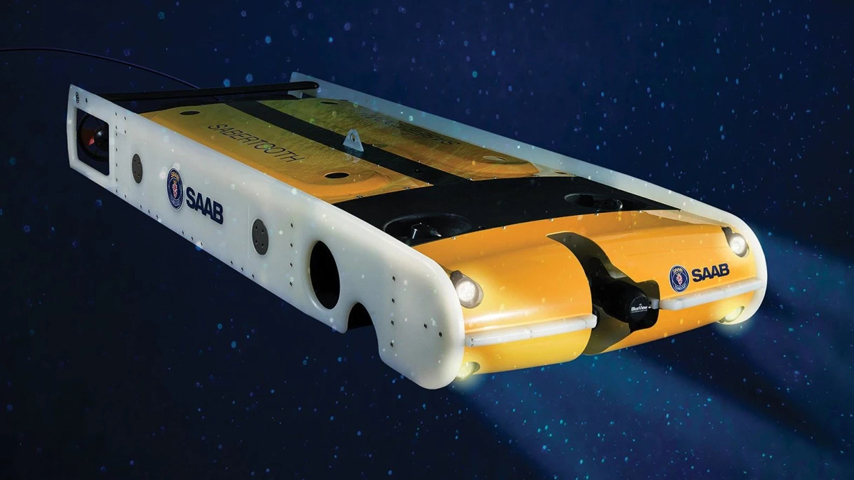

Moderator Chuck Thorpe formally set the stage, informing the audience as to how robots are changing the manufacturing environment. He mentioned that we used to think of the words dangerous, dull, and disappearing when we thought of manufacturing. Now, however, we think of three new Ds: (1) Dexterous: Robots can reach places and perform tasks that humans simply cannot or should not. For instance, robots today can reach into the ribs of an airplane wing, as well as the ribs of a cardiac patient. (2) Deeply integrated: Today, robotic technologies are built into the systems themselves. Smart systems don’t look like robots, they look like cars and cranes and other things, which the robotics are simply integrated into. (3) Disappearing…I Don’t Think So: New robotic technologies are encouraging new skills and jobs to arise. Thorpe ended with the idea that for further advancement, robotics needs mechanical engineering, and mechanical engineers need robotics, a connection that is often overlooked.

The first panelist to present was Howie Choset, who spoke to the relationship between robotics and jobs. He has a background in working with “snake robots” – highly flexible systems to go into very small places. Howie believes that flexibility, both in the robot structures and their skill, is the key to advancing the industry. Robotic systems are expensive and 98.5% of manufacturers in the U.S. are small- or medium-sized manufacturers who do not have the capital to invest in technology that cannot adapt to future changes. Howie also mentioned that paired with this idea of flexible robots is the need for flexible job training. Panelist Larry Sweet agreed with this point, and then spoke about the increased need for collaborative robotics.

Larry has observed that many manufacturers see the opportunity to grow if automation becomes more flexible. The key, he notes, is to balance the risk of adopting new technologies with opportunity which can be achieved through making systems more flexible for increased productivity. Collaborative robots, flexible robots, and mobile robots are all new types of technologies that will inject flexibility into the system, prompting innovation and increased productivity. Today, robots and humans are co-habiting manufacturing floors, but working separately. In order to advance, humans and robots, Larry suggests the need for the two to work together so that they can each preform the tasks the other cannot at the same time, on the same product.

Erik Nieves, an Industrial Robotics Engineer, spoke further about the impact of robotics on the small manufacturer. Most manufacturing that employs robots today is low-mix, high-volume production, meaning building the same thing over and over. Robots are extremely good at repetitive tasks, but they need to become better at doing high-mix, low-volume production. Erik noted that three-fourths of our industrial base is 20 employees or less, meaning the main place for growth in robotic manufacturing is with small companies.