Virus-Vanquishing Surface to Reduce Transmission

Virus-Vanquishing Surface to Reduce Transmission

If surfaces could stop viruses like the coronavirus in their tracks, we could defang the next potential pandemic. Researchers out of Queensland University of Technology have created that surface.

We are superficial creatures. Just about everything we do—opening the door to the fridge, sitting on the sofa watching TV, slicing open a patient in the operating room—involves interacting with surfaces. But we are not the only superficial creatures. Bacteria and viruses live and spread on those same planes. If we could alter our surfaces to make them less hospitable to these microbes, the transmission of disease would be dramatically reduced.

Prasad Yarlagadda, a professor of science and engineering at Brisbane’s Queensland University of Technology has created just such a surface.

For years he has worked to create a durable antibacterial surface through various means. To do so, he studied surfaces found in the animal kingdom: Shark and gecko skin, dragonfly and cicada wings.

“Geckos and dragonflies don’t use antibiotics,” Yarlagadda said. “When a dragonfly dies, the main part of the body disintegrates very quickly. But the wings remain for a long time—a few years. We looked at why.”

When the bacteria that break down a dragonfly’s body come in contact with the wings, nano pillars there puncture the microbe’s diaphragm, and its guts spill out.

Read More on Finding a Way Forward After the Pandemic

Yarlagadda had success imitating those nanostructures to create antibacterial surfaces. But the process he used—hydrothermal synthesis—was expensive. And the effect of the resultant nanostructure on viruses was unknown.

“Killing bacteria is very easy, but deactivation of viruses is difficult,” he said.

In anticipation of the spread of a SARS-like virus, he worked to find a nano-architecture that would also neutralize viruses, but with a smaller price tag. He turned to a far cheaper method, wet etching. He soaked disks of aluminum 6063—the same stuff that hospital beds and much of our medical equipment is made of—in sodium hydroxide.

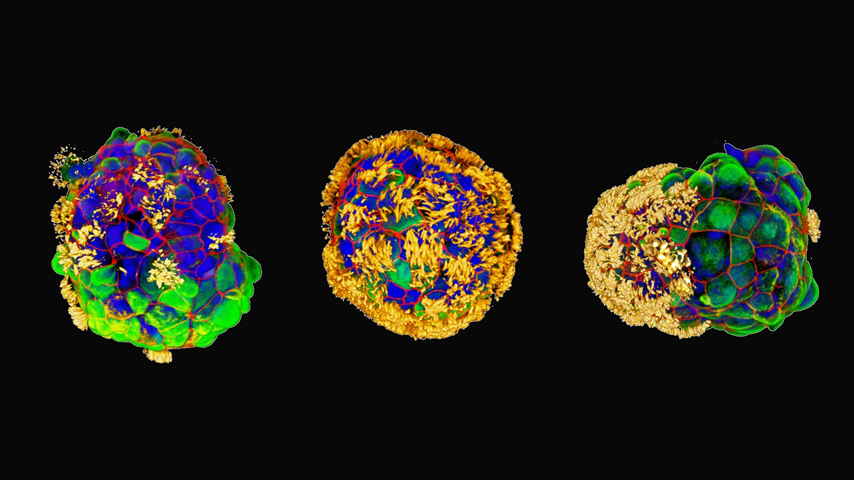

The newly etched aluminum slew bacteria—Pseudomonas aeruginosa and Staphylococcus aureus—easily. Yarlagadda also exposed the surface to respiratory syncytial virus and rhinovirus. After 90 minutes, 80 percent of the viruses were deactivated. After 24 hours that percentage moved up to near 100. Unlike bacteria, however, the mechanism of the viral deactivation is yet unknown.

Of course, any material destined for use in a hospital will have to be able to withstand the daily rigors found there. So Yarlagadda submitted his aluminum to 1,000 pummels from “a flat end conical indenter.”

Scanning electron microscopy revealed that the etched nanostructures looked pretty much the way they did before the attack.

Though those structures vanquish bacteria and viruses, doctors and patients wouldn’t notice the difference. To the human, the etching is undetectable by sight or touch. “You don’t feel it,” Yarlagadda said. “It looks very smooth.”

Watch Video: Killing the Coronavirus with Disinfection Robots

The next step is to turn to other materials widely used in medicine: steel.

“With stainless steel, you have to be a lot more careful,” Yarlagadda said. “We haven’t yet produced a successful pattern.” Yarlagadda and his colleagues will likely try a variety of etching techniques before they find the right nanostructure.

With Yarlagadda’s etched surfaces, hospitals may be safer from superbugs and the world might be better prepared for the next pandemic. “We are fortunate to be doing this research at this time,” Yarlagadda said.

Michael Abrams is a technology writer based in Westfield, N.J.

Prasad Yarlagadda, a professor of science and engineering at Brisbane’s Queensland University of Technology has created just such a surface.

For years he has worked to create a durable antibacterial surface through various means. To do so, he studied surfaces found in the animal kingdom: Shark and gecko skin, dragonfly and cicada wings.

Neutralizing Viruses

“Geckos and dragonflies don’t use antibiotics,” Yarlagadda said. “When a dragonfly dies, the main part of the body disintegrates very quickly. But the wings remain for a long time—a few years. We looked at why.”

When the bacteria that break down a dragonfly’s body come in contact with the wings, nano pillars there puncture the microbe’s diaphragm, and its guts spill out.

Read More on Finding a Way Forward After the Pandemic

Yarlagadda had success imitating those nanostructures to create antibacterial surfaces. But the process he used—hydrothermal synthesis—was expensive. And the effect of the resultant nanostructure on viruses was unknown.

“Killing bacteria is very easy, but deactivation of viruses is difficult,” he said.

In anticipation of the spread of a SARS-like virus, he worked to find a nano-architecture that would also neutralize viruses, but with a smaller price tag. He turned to a far cheaper method, wet etching. He soaked disks of aluminum 6063—the same stuff that hospital beds and much of our medical equipment is made of—in sodium hydroxide.

The newly etched aluminum slew bacteria—Pseudomonas aeruginosa and Staphylococcus aureus—easily. Yarlagadda also exposed the surface to respiratory syncytial virus and rhinovirus. After 90 minutes, 80 percent of the viruses were deactivated. After 24 hours that percentage moved up to near 100. Unlike bacteria, however, the mechanism of the viral deactivation is yet unknown.

Of course, any material destined for use in a hospital will have to be able to withstand the daily rigors found there. So Yarlagadda submitted his aluminum to 1,000 pummels from “a flat end conical indenter.”

Safer Future

Scanning electron microscopy revealed that the etched nanostructures looked pretty much the way they did before the attack.

Though those structures vanquish bacteria and viruses, doctors and patients wouldn’t notice the difference. To the human, the etching is undetectable by sight or touch. “You don’t feel it,” Yarlagadda said. “It looks very smooth.”

Watch Video: Killing the Coronavirus with Disinfection Robots

The next step is to turn to other materials widely used in medicine: steel.

“With stainless steel, you have to be a lot more careful,” Yarlagadda said. “We haven’t yet produced a successful pattern.” Yarlagadda and his colleagues will likely try a variety of etching techniques before they find the right nanostructure.

With Yarlagadda’s etched surfaces, hospitals may be safer from superbugs and the world might be better prepared for the next pandemic. “We are fortunate to be doing this research at this time,” Yarlagadda said.

Michael Abrams is a technology writer based in Westfield, N.J.