Robotics Blog: Lowering the Barrier to Automation with One-Stop-Shops

Robotics Blog: Lowering the Barrier to Automation with One-Stop-Shops

Full automation solutions, complete with hardware and software options, are helping new companies enter the world of robotics.

Despite a global pandemic, the automation industry has seen a boon. According to the International Federation of Robotics (IFR), the installation of industrial robotics bounced back in 2021. In 2020, the worldwide installation of industrial robots was 384,000, and in 2021, that number jumped to 435,000, surpassing the number of robots installed in 2018.

The main reason for this rise was the adoption of robots by new industries. The IFR reported that e-commerce consumer behavior drove the installation of thousands of robots in business segments that were not using robots just a mere five years ago.

“In an effort to address labor shortages, companies that have not previously considered automation will reconsider. Businesses that rely on service workers, such as retail and restaurants, are unable to fill job openings, and as a result, we can expect to see them invest in automation to meet patrons’ needs,” reported the IFR in its recent “Top 5 Robot Trends of 2022.”

Read our Infographic: The Strength and Versatility of Robotic Grippers

A significant factor of this increased adoption is that the technology barrier has been lowered dramatically. In their trends report, the IFR stated that low-cost robotics are spreading among companies due to easiness of implementation, pre-configured applications, manual guidance programming, and standardization of grippers, sensors, and controllers.

Luckily for first-time automation customers, online marketplaces to buy robotic equipment already exist. Directindustry.com, for example, sells collaborative robots, SCARA robots, welding robots, grippers, tool changers, and robotic controllers. Users that have experience with automation can pick and choose their parts as easily as buying goods from Amazon. However, these types of websites still require that the customer has some familiar knowledge with how to install and program robots.

New marketplaces are now appearing that take the ease of implementation a step further, providing installation and software customization. Automation solution companies are now offering bundled hardware packages that come with pre-installed easy-to-program software, creating one-stop-shops for those looking to introduce automation into their workflows easily.

Recommended for You: Are You Ready to Trust Robotic Systems?

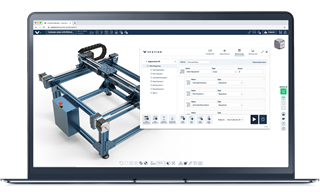

Vention, a manufacturing automation platform founded in 2016, designs complete robotic automated systems and is used by companies like Stryker and Boeing. Its website features a drag-and-drop parts library, allowing users to customize their robots to their specific needs. As customers select their robotic hardware, they can also create automation programs within Vention’s MachineLogic software. In this code-free editor, users can define the actuators’ movement and the robot’s actual path. Once the unit is assembled, the software will be pre-programmed into the controls and be ready to go. The automation solution comes with auto-generated assembly drawings, ensuring all the parts fit and work together out of the box.

Vention sells robots from well-known vendors such as Universal Robots, Fanuc, and Epson. It has also partnered with companies like OnRobot to sell their plug-and-play tools and grippers for collaborative robots.

Another company entering the automated solutions market is igus, a motion plastics company known for plastic bearings and plastic cable chains. The firm recently launched RBTX.com, a marketplace for low-cost robotics solutions. Customers can design complete automated solutions that include everything from the robot, cables, and even the programming software. Some of the solutions offered are for flexible bin picking, laboratory automation, palletizing applications, or electronics part sorting.

“Companies need cost-effective and, above all, easy-to-operate solutions that any company can use without incurring excessive costs and integration effort. And it is precisely for these applications that we have developed various low-cost kinematic systems with the help of our plastics expertise: articulated arm robots, linear robots, Scara, and Delta robots,” said Alexander Mühlens, head of low-cost automation at igus.

Editor’s Pick: Robots Replace Aging Workers

igus designs and sells their own robots. Their newest robotic arm is the ReBeL cobot with six degrees of freedom. The robot is electronically actuated and has a load capacity of two kilograms. The cobot is ideal for companies looking for pick and place or mobile applications. Their low-cost automation solutions leverage 3D-printed parts and plastic materials, making the robots lightweight and easier to produce, resulting in shorter lead times. It also creates robotic systems that are energy-efficient and versatile, easily installed or moved depending on where along the manufacturing process they are needed.

For both Vention and igus, customer support is vital. Each site offers access to an automation expert who can help the customer design and customize their automation solution. This will help first-time buyers with the process of introducing automated solutions.

With the barrier to enter automation becoming easier to climb, automation and robotic solutions will continue to see a signification rise in adoption.

Carlos M. González is special projects manager.

The main reason for this rise was the adoption of robots by new industries. The IFR reported that e-commerce consumer behavior drove the installation of thousands of robots in business segments that were not using robots just a mere five years ago.

“In an effort to address labor shortages, companies that have not previously considered automation will reconsider. Businesses that rely on service workers, such as retail and restaurants, are unable to fill job openings, and as a result, we can expect to see them invest in automation to meet patrons’ needs,” reported the IFR in its recent “Top 5 Robot Trends of 2022.”

Read our Infographic: The Strength and Versatility of Robotic Grippers

A significant factor of this increased adoption is that the technology barrier has been lowered dramatically. In their trends report, the IFR stated that low-cost robotics are spreading among companies due to easiness of implementation, pre-configured applications, manual guidance programming, and standardization of grippers, sensors, and controllers.

Luckily for first-time automation customers, online marketplaces to buy robotic equipment already exist. Directindustry.com, for example, sells collaborative robots, SCARA robots, welding robots, grippers, tool changers, and robotic controllers. Users that have experience with automation can pick and choose their parts as easily as buying goods from Amazon. However, these types of websites still require that the customer has some familiar knowledge with how to install and program robots.

New marketplaces are now appearing that take the ease of implementation a step further, providing installation and software customization. Automation solution companies are now offering bundled hardware packages that come with pre-installed easy-to-program software, creating one-stop-shops for those looking to introduce automation into their workflows easily.

Recommended for You: Are You Ready to Trust Robotic Systems?

Vention, a manufacturing automation platform founded in 2016, designs complete robotic automated systems and is used by companies like Stryker and Boeing. Its website features a drag-and-drop parts library, allowing users to customize their robots to their specific needs. As customers select their robotic hardware, they can also create automation programs within Vention’s MachineLogic software. In this code-free editor, users can define the actuators’ movement and the robot’s actual path. Once the unit is assembled, the software will be pre-programmed into the controls and be ready to go. The automation solution comes with auto-generated assembly drawings, ensuring all the parts fit and work together out of the box.

Vention sells robots from well-known vendors such as Universal Robots, Fanuc, and Epson. It has also partnered with companies like OnRobot to sell their plug-and-play tools and grippers for collaborative robots.

Another company entering the automated solutions market is igus, a motion plastics company known for plastic bearings and plastic cable chains. The firm recently launched RBTX.com, a marketplace for low-cost robotics solutions. Customers can design complete automated solutions that include everything from the robot, cables, and even the programming software. Some of the solutions offered are for flexible bin picking, laboratory automation, palletizing applications, or electronics part sorting.

“Companies need cost-effective and, above all, easy-to-operate solutions that any company can use without incurring excessive costs and integration effort. And it is precisely for these applications that we have developed various low-cost kinematic systems with the help of our plastics expertise: articulated arm robots, linear robots, Scara, and Delta robots,” said Alexander Mühlens, head of low-cost automation at igus.

Editor’s Pick: Robots Replace Aging Workers

igus designs and sells their own robots. Their newest robotic arm is the ReBeL cobot with six degrees of freedom. The robot is electronically actuated and has a load capacity of two kilograms. The cobot is ideal for companies looking for pick and place or mobile applications. Their low-cost automation solutions leverage 3D-printed parts and plastic materials, making the robots lightweight and easier to produce, resulting in shorter lead times. It also creates robotic systems that are energy-efficient and versatile, easily installed or moved depending on where along the manufacturing process they are needed.

For both Vention and igus, customer support is vital. Each site offers access to an automation expert who can help the customer design and customize their automation solution. This will help first-time buyers with the process of introducing automated solutions.

With the barrier to enter automation becoming easier to climb, automation and robotic solutions will continue to see a signification rise in adoption.

Carlos M. González is special projects manager.