New Roof Both Cools and Heats

New Roof Both Cools and Heats

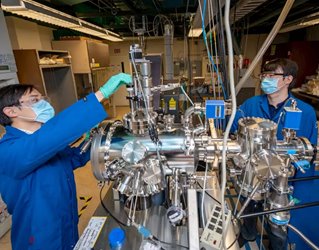

A thin-film, smart-roof coating made from vanadium dioxide could save the average U.S. household about 10 percent in electricity costs. Credit: Thor Swift/Berkeley Lab

“Cool-roof” systems that exist today cool homes by reflecting sunlight from their surfaces. Such roofs can reduce energy costs in summer. These systems also radiate heat in the winter through the process of radiative cooling. That helps drive up heating costs.

Now, however, a research team at University of California-Berkeley, led by Junqiao Wu, a professor in the Department of Materials Science and Engineering, has developed a smart-roof coating that keeps homes warm during the winter and cool during the summer, without consuming natural gas or electricity.

This new material—called “temperature-adaptive radiative coating” or TARC—can enable energy savings by automatically turning off the radiative cooling in the winter. This groundbreaking technology outperforms commercial cool-roof systems in energy savings by about 10 percent.

Considerable attention has been given to maximizing the radiative cooling power of roof coating in the hot daytime using static, cooling-optimized material properties. However, the resultant overcooling at night or during the winter season increases heating costs.

As a materials physicist, Wu has been interested in phase-change materials and phase transitions throughout his career. He was studying passive radiative cooling technology when he noticed “that the energy saving needs to be considered holistically from the all-season perspective—not only cooling in hot weather but also warming in cold weather,” he said.

Editor's Choice: What Termites Can Teach Engineers

For example, in passive cooling technologies, the deepest sub-ambient radiative cooling is pursued where solar absorption is maximally avoided—close to zero. “However,” said Wu, “when looking at the problem from the all-season perspective—including both the cooling needs in the summer and the heating needs in the winter—we found that the solar absorption should instead be optimized at a value around 30 percent, varying slightly depending on the local climate.”

One way to expand the radiative cooling from cooling-only into cooling-and-warming is to design the material’s radiative emissivity to automatically adapt to environmental temperature. Hence the team decided to try a phase-change material—specifically vanadium dioxide. Electrons in vanadium dioxide conduct electricity well without conducting much heat—a unique combination. “This behavior contrasts with most other metals where electrons conduct heat and electricity proportionally,” said Wu.

To see how vanadium dioxide would perform as a roof system, Wu and his team engineered a 2-centimeter-by-2-centimeter TARC thin-film device and installed it in Wu’s home to test viability in a real-world environment. Data was recorded continuously in response to changes in direct sunlight and outdoor temperature from a TARC sample, a commercial dark roof sample, and a commercial white roof sample over multiple days. The team then used the data to simulate how TARC would perform across 15 different climate zones across in the U.S., using more than 100,000 building energy simulations.

The researchers discovered that TARC outperformed existing roof coatings for energy saving in 12 of the 15 climate zones, especially in regions with wide temperature variations between day and night. “The biggest surprise was that the switch in thermal emissivity was found to have a large contrast, from 0.2 at low temperatures to 0.9 at high temperatures,” said Wu. “This was close to the ideal, simulated values of emissivity in the two states. With TARC installed, the average household in the U.S. could save up to 10 percent electricity.”

The team’s next steps are to scale up TARC to fit larger areas, with easier use and lower cost, and to add increased functionality. “We are making good progress and will work with industry to bring the technology to the market,” said Wu. Other possible TARC applications include serving as a thermally protective coating on consumer products, cars, satellites, and even clothing.

Selected for You: A Linear Motor to Cut Cooling Costs

“Our all-season roof coating automatically switches from keeping you cool to warm, depending on outdoor air temperature,” said Wu. “This is energy-free, emission-free air conditioning and heating, all in one device. Simple physics predicted TARC would work, but we were surprised it worked so well. We originally thought the switch from warming to cooling would not be so dramatic. Our simulations, outdoor experiments, and lab experiments proved otherwise—it is really exciting.”

Mark Crawford is a science and technology writer based in Corrales, N.M.

Now, however, a research team at University of California-Berkeley, led by Junqiao Wu, a professor in the Department of Materials Science and Engineering, has developed a smart-roof coating that keeps homes warm during the winter and cool during the summer, without consuming natural gas or electricity.

This new material—called “temperature-adaptive radiative coating” or TARC—can enable energy savings by automatically turning off the radiative cooling in the winter. This groundbreaking technology outperforms commercial cool-roof systems in energy savings by about 10 percent.

Considerable attention has been given to maximizing the radiative cooling power of roof coating in the hot daytime using static, cooling-optimized material properties. However, the resultant overcooling at night or during the winter season increases heating costs.

As a materials physicist, Wu has been interested in phase-change materials and phase transitions throughout his career. He was studying passive radiative cooling technology when he noticed “that the energy saving needs to be considered holistically from the all-season perspective—not only cooling in hot weather but also warming in cold weather,” he said.

Editor's Choice: What Termites Can Teach Engineers

For example, in passive cooling technologies, the deepest sub-ambient radiative cooling is pursued where solar absorption is maximally avoided—close to zero. “However,” said Wu, “when looking at the problem from the all-season perspective—including both the cooling needs in the summer and the heating needs in the winter—we found that the solar absorption should instead be optimized at a value around 30 percent, varying slightly depending on the local climate.”

One way to expand the radiative cooling from cooling-only into cooling-and-warming is to design the material’s radiative emissivity to automatically adapt to environmental temperature. Hence the team decided to try a phase-change material—specifically vanadium dioxide. Electrons in vanadium dioxide conduct electricity well without conducting much heat—a unique combination. “This behavior contrasts with most other metals where electrons conduct heat and electricity proportionally,” said Wu.

Adapting to Temperature

To see how vanadium dioxide would perform as a roof system, Wu and his team engineered a 2-centimeter-by-2-centimeter TARC thin-film device and installed it in Wu’s home to test viability in a real-world environment. Data was recorded continuously in response to changes in direct sunlight and outdoor temperature from a TARC sample, a commercial dark roof sample, and a commercial white roof sample over multiple days. The team then used the data to simulate how TARC would perform across 15 different climate zones across in the U.S., using more than 100,000 building energy simulations.

The researchers discovered that TARC outperformed existing roof coatings for energy saving in 12 of the 15 climate zones, especially in regions with wide temperature variations between day and night. “The biggest surprise was that the switch in thermal emissivity was found to have a large contrast, from 0.2 at low temperatures to 0.9 at high temperatures,” said Wu. “This was close to the ideal, simulated values of emissivity in the two states. With TARC installed, the average household in the U.S. could save up to 10 percent electricity.”

The team’s next steps are to scale up TARC to fit larger areas, with easier use and lower cost, and to add increased functionality. “We are making good progress and will work with industry to bring the technology to the market,” said Wu. Other possible TARC applications include serving as a thermally protective coating on consumer products, cars, satellites, and even clothing.

Selected for You: A Linear Motor to Cut Cooling Costs

“Our all-season roof coating automatically switches from keeping you cool to warm, depending on outdoor air temperature,” said Wu. “This is energy-free, emission-free air conditioning and heating, all in one device. Simple physics predicted TARC would work, but we were surprised it worked so well. We originally thought the switch from warming to cooling would not be so dramatic. Our simulations, outdoor experiments, and lab experiments proved otherwise—it is really exciting.”

Mark Crawford is a science and technology writer based in Corrales, N.M.