5 Industries Where Big Data Brings Big Returns

5 Industries Where Big Data Brings Big Returns

Agriculture and other industries are using newfound knowledge to drive growth.

Big Data. The term describes the amount of data an organization can access—which, today, is tremendous. But it doesn’t stop there. The data needs to be analyzed, sliced, chopped, and put it to use to grow a business, improve customer service, slow downtime, speed a supply chain, and much more.

The finance and retail industries are famous for gleaning insights from their data. Now many other industries have joined them, including those in the engineering realm.

Whatever the industry, putting the data to work is a huge task in this time of machine learning, Internet of Things, artificial intelligence, and many more intelligent systems that continually return great swaths of pertinent information.

Here are five industries that seem to be overcoming those hurdles and how they’re putting big data to use for them.

The construction industry now has access to feedback garnered through a host of sensors and software programs. The industry is using drones that give feedback on the state of the project and robotic bricklayers that—with the help of artificial intelligence— will grow better and better at their jobs.

The industry also deploys digital solutions that extend beyond the construction site. Supply chain planning addresses challenges to disruption while logistics software aids in transporting the goods to the job site on time, said Orsolya Nagy, a research consultant for businesses interested in Construction 4.0 technologies.

More for You: How Manufacturers Implement Digital Transformation

The manufacturing sector is expected to grow the fastest in its use of data derived from artificial intelligence, according to industry analyst firm Gartner.

This is no surprise. Manufacturers can access much more operational information than ever before, especially with the advent of Industry 4.0, which aims to connect all aspects of a plant, and the Internet of Things which returns real-world operating information.

Data is easier to access, with a low barrier to entry for implementing IoT devices and smart factory equipment, said Junliang Wang, a professor at the Institute of Artificial Intelligence, Donghua University, Shanghai.

He and his team analyzed published information about big data technologies used for manufacturing. They published their results in the June 2021 issue of the Journal of Manufacturing Systems.

Manufacturers measure many aspects of their business and use the information for insight that help:

You may have heard about farmers who use drones to monitor their crops. You may not have realized this was a story about big data.

Unsurprisingly agriculture—an industry with little prior use of technology—has seen the most momentum in terms of agricultural technologies, said Tanha Talaviya a professor of computer engineering at Indus University Ahmedabad, Gujarat, India.

Talaviya co-authored an article on using artificial intelligence to optimize herbicide and pesticide on crops. It appeared in the journal Artificial Intelligence in Agriculture, Volume 4, 2020.

Like manufacturing, the agricultural sector has access to more feedback to work with than ever before. IoT sensors—whether plugged into tractors or and flying on drones—give direct feedback on variables like plant growth, soil saturation, and pesticide levels, she said.

In fact, farmers can now monitor the growth of an individual plant, should they care to. Currently, they’re mainly using data to plan where to plant crops and how much water and pesticide to apply to them, Talaviya said.

Big data and engineering design are becoming increasingly intertwined. Today’s design tools provide an increasing the amount of data that can be used for all phases of engineering design, said Filippo Chiarello, assistant professor of strategic and competitive intelligence at the University of Pisa.

Editor’s Pick: Data Science Is the New Engineering Tool

“Data science is changing the way organizations design their products and is re-shaping their approaches to using data during the engineering design process,” he said.

Chiarello co-authored a paper on engineering design and data science, which appeared in the March 2021 journal Computers for Industry. The entire edition of the journal was given over to data science for engineering design.

Engineers will have a more structured and reproducible process if they can reuse past design information. They can also take into account information they’ve gained about customer needs, Chiarello said.

He addresses the two types of data useful for design engineers: information about the product and its past design, and data from outside the company, such as customer feedback or supplier problems.

The use of analysis and modeling data is only now making its way into the realm of consumer product design, according to the authors.

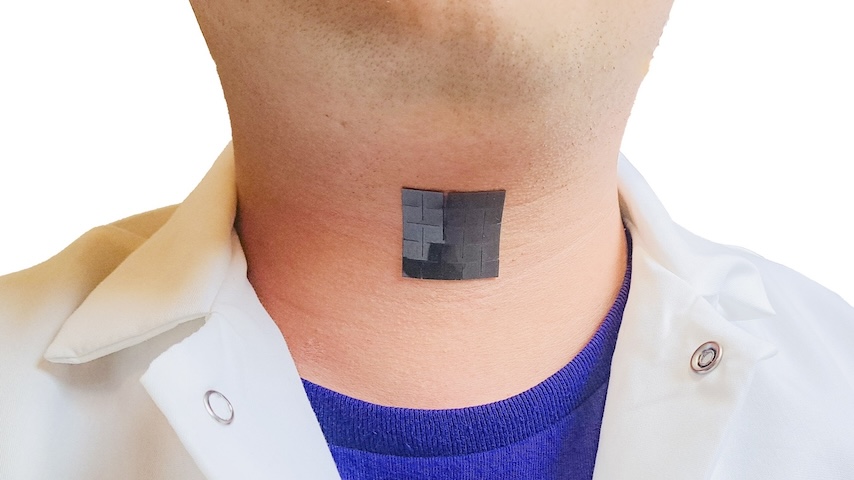

Recent developments in the generation and analysis of patient data could usher in a new era of precision medicine, according Gartner. It recently released “Healthcare a Digital Transformation,” a paper that outlines innovations.

With new technologies that track and measure patient data, doctors can tailor a medication and treatment plan to an individual patient. It’s the predictive analysis tools that especially have the potential to enable the diagnosis, treatment, and prevention of disease at a highly personalized level, according to Gartner.

Reader’s Choice: The Digital Road to Cleaner Energy

A drawback is that these systems come slowly, as predictive models aren’t easy to populate. Creating a predictive model depends upon the software’s capacity to organize, manage, and interpret the huge amounts of data involved, the Gartner paper said.

Today big data cuts across all industries. But, over the past five to eight years, some industries—thanks to new technologies—have seen a huge uptick in the amount of information and feedback they can access.

Experts predict an avalanche of changes within these industries as they learn what big data can do for them.

Jean Thilmany writes about engineering and technology from Saint Paul, Minn.

The finance and retail industries are famous for gleaning insights from their data. Now many other industries have joined them, including those in the engineering realm.

Whatever the industry, putting the data to work is a huge task in this time of machine learning, Internet of Things, artificial intelligence, and many more intelligent systems that continually return great swaths of pertinent information.

Here are five industries that seem to be overcoming those hurdles and how they’re putting big data to use for them.

Construction

The construction industry now has access to feedback garnered through a host of sensors and software programs. The industry is using drones that give feedback on the state of the project and robotic bricklayers that—with the help of artificial intelligence— will grow better and better at their jobs.

The industry also deploys digital solutions that extend beyond the construction site. Supply chain planning addresses challenges to disruption while logistics software aids in transporting the goods to the job site on time, said Orsolya Nagy, a research consultant for businesses interested in Construction 4.0 technologies.

More for You: How Manufacturers Implement Digital Transformation

Manufacturing

The manufacturing sector is expected to grow the fastest in its use of data derived from artificial intelligence, according to industry analyst firm Gartner.

This is no surprise. Manufacturers can access much more operational information than ever before, especially with the advent of Industry 4.0, which aims to connect all aspects of a plant, and the Internet of Things which returns real-world operating information.

Data is easier to access, with a low barrier to entry for implementing IoT devices and smart factory equipment, said Junliang Wang, a professor at the Institute of Artificial Intelligence, Donghua University, Shanghai.

He and his team analyzed published information about big data technologies used for manufacturing. They published their results in the June 2021 issue of the Journal of Manufacturing Systems.

Manufacturers measure many aspects of their business and use the information for insight that help:

- Make decisions on predictive maintenance

- Customize products or orders

- Cut operating costs

- Speed supply chain

- Track products to end-of-life for proper disposal

- Perform advanced planning

- Automate certain functions

Agriculture

You may have heard about farmers who use drones to monitor their crops. You may not have realized this was a story about big data.

Unsurprisingly agriculture—an industry with little prior use of technology—has seen the most momentum in terms of agricultural technologies, said Tanha Talaviya a professor of computer engineering at Indus University Ahmedabad, Gujarat, India.

Talaviya co-authored an article on using artificial intelligence to optimize herbicide and pesticide on crops. It appeared in the journal Artificial Intelligence in Agriculture, Volume 4, 2020.

Like manufacturing, the agricultural sector has access to more feedback to work with than ever before. IoT sensors—whether plugged into tractors or and flying on drones—give direct feedback on variables like plant growth, soil saturation, and pesticide levels, she said.

In fact, farmers can now monitor the growth of an individual plant, should they care to. Currently, they’re mainly using data to plan where to plant crops and how much water and pesticide to apply to them, Talaviya said.

Engineering design

Big data and engineering design are becoming increasingly intertwined. Today’s design tools provide an increasing the amount of data that can be used for all phases of engineering design, said Filippo Chiarello, assistant professor of strategic and competitive intelligence at the University of Pisa.

Editor’s Pick: Data Science Is the New Engineering Tool

“Data science is changing the way organizations design their products and is re-shaping their approaches to using data during the engineering design process,” he said.

Chiarello co-authored a paper on engineering design and data science, which appeared in the March 2021 journal Computers for Industry. The entire edition of the journal was given over to data science for engineering design.

Engineers will have a more structured and reproducible process if they can reuse past design information. They can also take into account information they’ve gained about customer needs, Chiarello said.

He addresses the two types of data useful for design engineers: information about the product and its past design, and data from outside the company, such as customer feedback or supplier problems.

The use of analysis and modeling data is only now making its way into the realm of consumer product design, according to the authors.

Healthcare

Recent developments in the generation and analysis of patient data could usher in a new era of precision medicine, according Gartner. It recently released “Healthcare a Digital Transformation,” a paper that outlines innovations.

With new technologies that track and measure patient data, doctors can tailor a medication and treatment plan to an individual patient. It’s the predictive analysis tools that especially have the potential to enable the diagnosis, treatment, and prevention of disease at a highly personalized level, according to Gartner.

Reader’s Choice: The Digital Road to Cleaner Energy

A drawback is that these systems come slowly, as predictive models aren’t easy to populate. Creating a predictive model depends upon the software’s capacity to organize, manage, and interpret the huge amounts of data involved, the Gartner paper said.

Today big data cuts across all industries. But, over the past five to eight years, some industries—thanks to new technologies—have seen a huge uptick in the amount of information and feedback they can access.

Experts predict an avalanche of changes within these industries as they learn what big data can do for them.

Jean Thilmany writes about engineering and technology from Saint Paul, Minn.